AEB-L Stainless Blade Steel

- Gift wrapping:

- Options available

Description

AEB-L Stainless Blade Steel

Razor blade steel from Uddeholm, developed for razor blades and scalpels but a popular bladesmith choice for small to medium sized blades of all styles.

Fine grained (small carbides), easy to sharpen, and reasonably easy to heat treat.

A specialist steel manufactured to combine ease of production with good edge retention and high corrosion resistance.

A very tough stainless steel, tougher than for instance 52100, D2, Elmax, CPM-154.

(Bjorn: having made quite a few chef knives in it, and used ourselves at home AEB-L knives for a couple of years, I really like it. It grinds and hand finishes well, as well as takes a really even etch if wanting to etch or etch and then stone wash)

Heat Treatment: the short version

Requires temperature control, like a thermocouple in gas forge, or better yet a kiln.

Heat to 1066 and hold for 15 min, quench in oil.

Put into kitchen freezer (as cold as you can get) for 10 mins.

Temper in 177 C for 1 hour > cool under tap > another 1 hours at 177 C

More detail on the heat treatment profiles for AEB-L: LINK

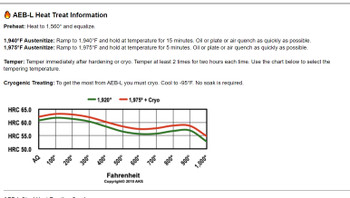

3 different profiles recommended by the Knifesteelnerd.com, depending on if you will do a freeze step between quenching and tempering.

If not having access to cryo equipment, we recommend profile 2, using a kitchen fridge freezer.

Hardening 1: Heat to 1052 C and hold for 15 min, quench in oil or between plates.

Hardening 2: Heat to 1066 C and hold for 15 min, quench in oil or beteween plates then deep freezer at -20 C with 1 min hold time.

Hardening 3: Heat to 1080 C and hold for 15 min, quench in oil or between plates then cryo treat at -70 C with 1 min hold time.

Tempering: 2 x 2 hours each time is probably best, Knifesteelnerds.com tests use 1 hour each time:

--150 C: Hardening 1: 60 HRC, Hardening 3: 63 HRC

--200 C : Hardening 1: 58 HRC, Hardening 2: approx 59 HRC, Hardening 3: 61 HRC

--250 C: Hardening 1: 55 HRC, Hardening 3: 59 HRC

Custom knifemaker Devin Thomas has some great info on his site, quoted here:

Few know what AEB-L steel is, and those that do, only have heard that it is similar to 440B or 440A. The only similarities between AEB-L and 440B or 440A is the amount of carbon. The fact that AEB-L has only 12.8% chromium by weight compared to the 16-17% in 440A and 440B makes the steels quite different. AEB-L is more similar to a stainless 52100 than 440A...

AEB-L naturally forms what is called the K2 carbide, the harder of the two chromium carbides, compared to the K1 carbide, which is formed in steels such as 440C. The K2 carbide is about 79 on the Rockwell C scale, compared to 72 for the K1 carbide. Through proper heat treatment, AEB-L has fine, evenly distributed K2 carbides. AEB-L lies almost perfectly on what is called the "Carbon Saturation Line", which means that all of the carbides formed are precipitated carbides, not primary carbides like are formed in 440C, and there is more carbon and a similar amount chromium in solution as compared to 440C. Primary carbides are very large. So, through a balanced composition, AEB-L has excellent toughness, edge retention, workability, ease of sharpening, and ease of polishing.

Roman Landes and John Verhoeven have both done different tests with AEB-L. In CATRA testing Dr. Verhoeven found AEB-L to outcut 52100, 1086, and Wootz damascus. He also found AEB-L to be able to take a smaller edge radius than 52100 in controlled sharpening tests. Roman Landes found AEB-L to have greater edge stability, toughness, and wear resistance than 52100. Edge stability is a property that describes a steel's ability to hold a finely sharpened edge. 52100 is one of the most well respected carbon steels, and is well known for its small carbides, high toughness, and high edge stability, so it's impressive that AEB-L was able to beat it in these categories, while also having greater wear resistance and being a stainless steel. Many users have reported that AEB-L sharpens as easily as any other carbon steel they have used.

*Our understanding after reading several recommendations from US makers, aiming to provide a baseline suggestion.

Chemical composition:

C Si Mn P max S max Cr 0,67% 0,40% 0,60% 0,025% 0,006% 13,0%