What Knife Steel to Buy? How to compare steels?

Choosing the the right steel type for knife making

Are you looking for flat steel bars for making blades but unsure of how to choose the right type for your need? Look no further, here is a quick buyer’s guide to some of the more popular steel flat bar types used by knife makers. We will cover what you need to know to select the steel bar for your next project. Covering both quality and performance and trying to differentiate what each type is especially suited for.

This is a guide to the best knife steel to buy.

Different types of steel

Blade steel comes in many shapes, we will here refer to them as flat bar while many come in different dimensions as well as round stock or full sheets. Most makers start with flat bar in either kitchen knife thickness or thicker if making more “outdoor style” blades. To help decide what steel alloy type is right for your next project, here are some types of steel bar to give you a starting point.

All steel is made from iron with carbon added but from there different other elements are added to create different types (alloys) of steel. The different steels are designed for different use cases which dictate their strengths.

Carbon steel vs Stainless steel

- In the past carbon steel was superior to stainless steel, simply from the added chromium needed to make the steel “stainless” meant you had to give up iron, leading to poor edge retention. This is no longer the case, today science has taken stainless steels way past most of the traditional carbon steels and the happy result is that you today can select stainless steels with excellent edge retention qualities. Even “mid-level” stainless steels today have better edge retention than traditional carbon steels such as 1084 or 01 steel.

- Stainless steel means it will stain “less or not at all” and is by many preferred for kitchen knives and other knives that will need to get wet regularly. Especially if giving away or selling kitchen knives, it is by many seen as simpler to make them in stainless steels than having to explain how carbon steel knives discolour and patina with use. Lots of high-end kitchen knives are made in carbon steel (most Japanese knifes for instance) but these are for experienced chefs and customers who prefer the carbon edge and accept the patina as part of owning carbon steel knives.

Carbon steel for forging

- If forging or not having a lot of equipment > go with carbon steel.

- If having a gas forge with temperature control, wanting to make chef knives and not forging > go with stainless.

- There is more to this conversation but the traditional argument of carbon steels holding a better edge is simply no longer true - science have taken stainless steels way past the older carbon steels now.

- The use case for carbon steel is today more around wanting to forge, the fact that carbon steels are often cheaper and maybe more importantly the easy heat treatment.

- Flat steel bar is the most common format for blade steel, forging is mostly done from 3.5 mm and thicker dimensions. For kitchen knives and normal outdoor knives 3.5 x 38 mm or 3.5 x 50 mm flat steel bar is a good size, for bigger or longer blades 6 x 50 mm is a good forging size to start with. There are also sizes for swords, hammers, axes and other bigger dimensions: LINK

Edge retention vs toughness – the “impossible gap”

- The higher the carbon content of the steel (within reason), the better the edge retention will be. Simplified this is because the higher carbon helps create more carbides, very hard particles that are mixed into the steel structure and helps the edge last longer by wearing down slower than the steel itself.

- The problem with these carbides is that -simplified still – the higher carbon and more carbides you get, the more brittle the blade gets. Between the hard carbides and the “softer” steel around them, there is room for cracks to form when the blade is bent or exposed to shock.

- The result is that a high carbon steel is less tough than a lower carbon steel meaning you should consider if needing the toughness or not when deciding on a steel type.

- Note toughness also impacts how thin an edge can be – a tougher steel can have a thinner edge and therefore last longer than a more brittle steel needing a thicker edge to be strong enough for the use case.

- Result: For blades that need to be tough (machete, long camp knife, sword or anything else that will take a beating), a steel flat bar with very high carbon might not be the best choice while a lower carbon/ higher toughness might be better.

- For instance 5160 (often found as car leaf springs) is much tougher than 1084 or 1095 steel and might be a better choice for a machete – accepting that it will not hold an edge as long as 1084 or 1095. Or go 14C28N stainless and lose the ability to forge, but get high hardness, better edge retention – and it will not rust..

- The Austrian steel ApexUltra are promising to have “bridged the impossible gap”, having created a very high carbon steel that is still tougher than any comparable carbon steel in edge retention. This comes at a cost and is not a beginner steel, but for high-end kitchen knives it is seen by many as quite the super carbon steel.

Factors to consider when choosing blade steel

There are 3 key areas to consider when selecting the steel for a knife;

- 1.Heat treatment – do you have the experience and equipment for heat treating the steel, or are you sending it out for heat treatment? There is very little value in jumping from steel to steel and heat treating them poorly. Many experienced makers recommend picking one steel and learning that steel on your own equipment. Make it again and again and test your results. This is especially important if selling knives to know what you are handing over to a customer or collector. Then when you have a new use case like needing a stainless steel, experiment again with a single stainless steel until you can deliver the results you want. Jumping from one to the other steel, or not testing your results is shooting yourself in the foot simply because you are not sure how well what you are doing is working when put to hard use.

- 2.Carbon steel vs Stainless steel – does it need to be stainless? Are you giving it away, is it a kitchen knife or is it going to be used in a boat, when going fishing, or a bushcraft knife that might be wet in the sheath for days on end? Then stainless is possibly the simpler answer. Carbon steel can be forged – which is fun ! – and generally easier to heat treat, and holds a good edge so it is often more a case of “does it have to be stainless?”. Many might be surprised when looking at the testing data forstainless steels that are fairly easy to heat treat now having two or 3 times the edge retention of the traditional carbon steels.

- 3.Use case? Any special requirement that decides what direction to take this? Does it need high toughness needing a lower carbon steel that can really take a whack? Are you wanting a hamon, needing to use steels where this is easier like 1095 or W2 steels? Are you going for very high edge retention, wanting a knife that will hold an edge for a very, very long time? Maybe look at some of the stainless CPM steels or ApexUltra.

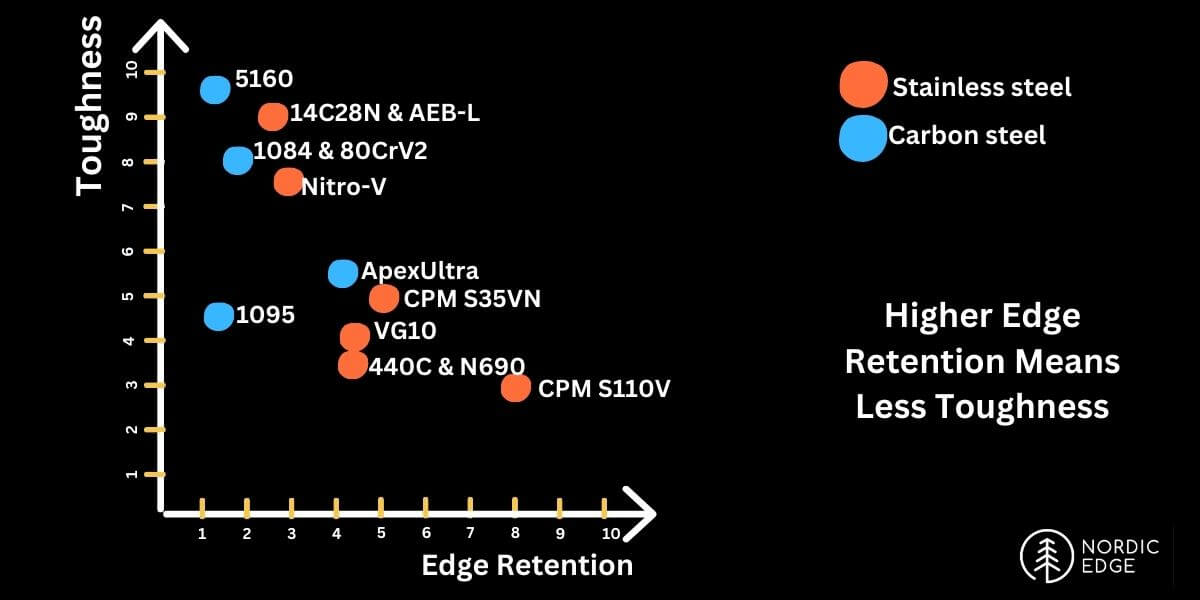

Toughness vs Edge Retention Comparison

How to read the chart:

- Steels are a compromise - you select mostly on edge vs toughness, then is it stainless or not

- Traditional carbon steels like 1084 have been bypassed by new stainless steels

- 5160: VERY tough, suitable for big blades. In the graph it looks like rubbish edge retention, but it will make a good big blade - the new stainless steels just make everything else look worse..

- 14C28N: Popular stainless steel that might look like not great edge retention - but high toughness and easy heat treatment makes it a popular steel that holds an edge TWICE as well as 1084.

- CPM "super steels" are part of the new powder-steel technology with very high edge retention.

- Some steels are the same or very similar "recipes" from different manufacturers, hitting the same point on the matrix.

Table below is taken from this article: KnifeSteelNerds.com

| Steel | Toughness | Edge Retention | Corrosion Resistance | Comment |

| 14C28N - stainless | 9 | 3 | 8.5 | Easy to heat treat, HIGH toughness and good edge retention (stainless) |

| 440C - stainless | 3.5 | 4.5 | 7.5 | Hard to grind and sand, GREAT edge retention |

| AEB-L - stainless | 9 | 3 | 7 | Easy to heat treat, HIGH toughness and good edge retention (stainless) |

| VG10 - stainless | 4 | 4.5 | 7.5 | Great edge retention, high hardness with good toughness. |

| CPM S35VN | 5 | 5 | 7.5 | Powder-technology super steel, ultra high carbon |

| CPM S110 | 3 | 8 | 9 | Powder-technology super steel, very high edge retention |

| 5160 – carbon | 9.5 | 1.5 | 0.5 | VERY tough, for big blades |

| 52100 – carbon | 8.5 | 2 | 0.5 | High toughness, small carbide size for keen edge. |

| 1084 – carbon | 8 | 1.5 | 0 | Easy to heat treat, easy to forge, medium edge retention, high toughness (carbon) |

| 80CrV2 – carbon | 8 | 1.5 | 0 | Slightly improved version of 1084, more complex heat treatment |

| ApexUltra - carbon | 5.5 | 4 | 0.5 | High edge retention carbon steel AND tough |

| 1095 – carbon | 4.5 | 1.5 | 0 | For Hamons, can be quenched in water |

| 01 – Carbon | 4.5 | 2 | 0.5 | Better edge retention but less tough than 1084 |

| D2 – carbon | 3.5 | 5 | 4.5 | “semi-stainless” with great edge retention |

*Full article with much more information at the end of the article from KnifeSteelNerds.com. Many factors such as treatment before quench, quench temp, quench media and tempering temperature affect both hardness and toughness for each steel. The above is only a summary report for some steels often used by makers.

Conclusion

Picking the right steel type for your project is important, almost as important as the heat treatment! So the key takeaway here is to pick a steel alloy type that is right for your use case – carbon, toughness, any special requirements – then get good at it, testing your results. But more than steel type, the performance of the final result in a given use case is mostly about edge geometry and heat treatment. Picking the right steel is only part of the job.

The above information is more a starting point and with some simplification and not “the final truth”, more something to give you an overview so you can pick one or two and do some more reading on these to see how they fit with what you want to achieve.

Should we give some recommendations for what steels to choose, those would be:

- Carbon steel: Start with 1084 and learn to heat treat this well. It is a very simple steel to succeed with and because it is probably the most popular steel with knife makers in Australia, it comes in so many different sizes – and there is lots of info online to learn how to heat treat it for your use case.

- Stainless: 14C28N or the older version 12C27 are very popular stainless steel flat bar with knife makers due to ease of heat treatment when branching into stainless steel. It also has much higher edge retention than 1084 and VERY high toughness so if you have a temperature-controlled gas forge this might be the steel that does it all.

- AEB-L and Nitro-V are very similar steels to 14C28N, AEB-L has slightly less corrosion resistance and Nitro-V slightly less toughness while still easy to heat treat, grind and sand.

- Hamons: Wanting to play with how to elegantly fail heat treating half the blade with beautiful results? Then go read up on 1095 or W2. The hamon is the line where the hardening stopped.

- Got a kiln or sending out for heat treatment? Try some of the new powder-technology "super steels" like CPM S35VN or S110 for extreme edge retention.

Sources: A big Thank You to Dr Larrin Thomas who is the brains behind the factual data and testing for toughness, edge retention and corrosion resistance used for this article. The article is only the author’s views and opinions based on personal experience and from reading Dr Thomas’ articles. Any factual data is the error of the author, refer to the full articles below and many, many others on Knifesteelnerds.com to learn more. Should you wish to support all the work he does for the knife making community, he is also on Patreon: LINK

https://knifesteelnerds.com/2021/10/19/knife-steels-rated-by-a-metallurgist-toughness-edge-retention-and-corrosion-resistance/ data background for toughness, edge retention and corrosion resistance, retrieved 05.07.2023

https://knifesteelnerds.com/2019/05/13/how-to-heat-treat-52100/ retrieved 05.07.2023

https://knifesteelnerds.com/2022/06/23/how-to-heat-treat-80crv2/ retrieved 05.07.2023

https://knifesteelnerds.com/2019/05/20/how-to-pick-the-best-steel-for-every-knife/ toughness affects how thin the edge can be, retrieved 05.07.2023.

https://www.patreon.com/Knifesteelnerds

Recent Posts

-

AWARDS 2024: How to Enter & Taking Photos to Score Well

On Wed 15th of May 2024 the live stream was on "How to Enter" and "What Photos to Take" or more impo …16th May 2024 -

1084: The Best Steel Ever?

Is 1084 Really the Best Steel Ever?!Well...it is a good steel, and very popular due to both making a …7th May 2024 -

AWARDS 2024 Kick-Off Presentation Slides

The Australian Knife Making Awards are back for 2024!Wed 1st of May 8 PM AEST your hosts this year R …2nd May 2024