Bladesmithing in Tosa, Japan

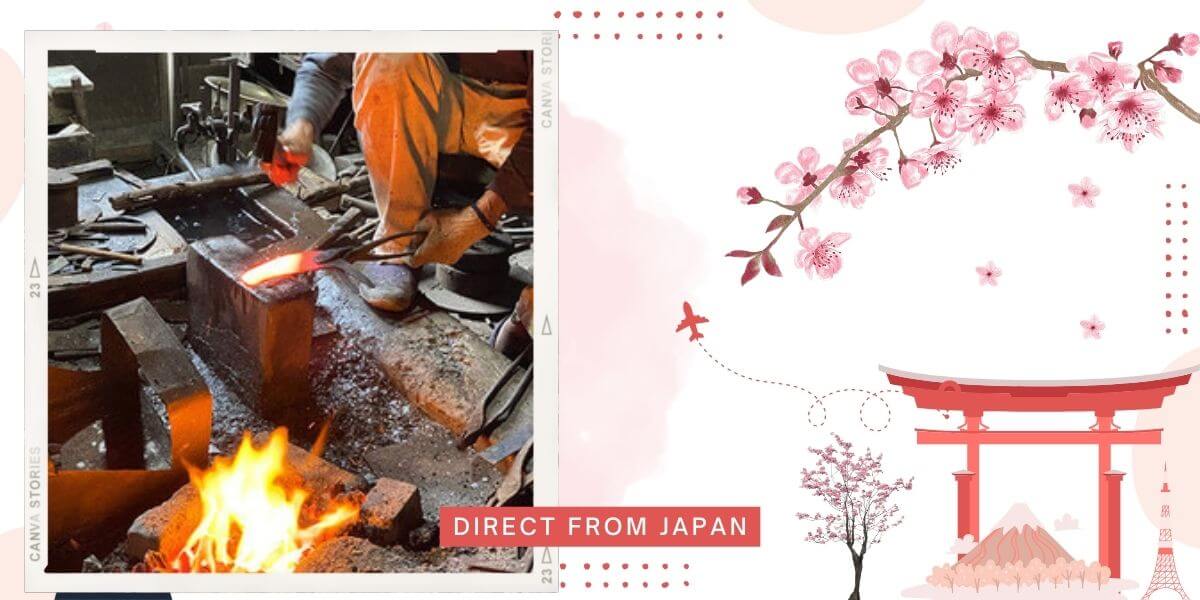

Bladesmithing has long, proud traditions in Japan where some traditional techniques are maintained and others are updated as new tools and materials enable even better blades to be created.

The famous Samurai swords are still made in Japan but for most of us, high-quality carbon steel chef blades are a more practical way to enjoy the results of these long traditions.

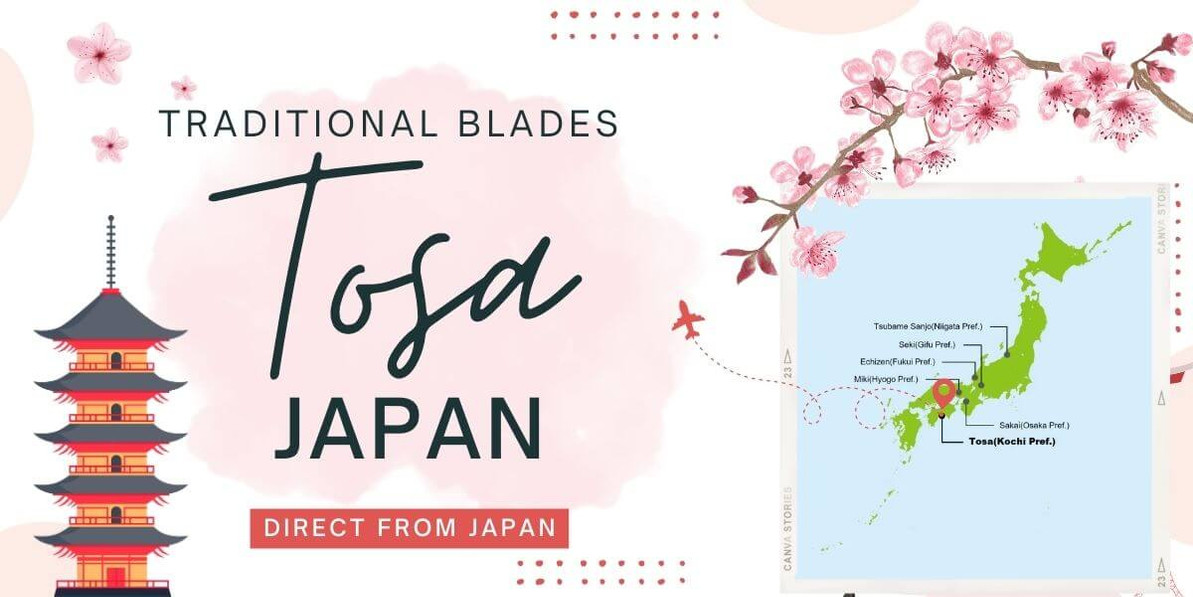

Tosa

One of the main centres for bladesmithing in Japan is Tosa, located on the Southern coast of the island of Shikoku. One thing that sets many makers in Tosa apart from other areas is that often the entire blade is completed by the same maker - unlike the traditional Japanese way of each craftsperson specialising in a certain part of the process. This is referred to as "free forging", allowing the artisan more freedom for individual style and finish.

San Mai - best of both worlds

Tosa blades are traditionally made in a san mai construction, inserting a piece of blade steel in a cladding of iron or mild steel. This helps create what Japanese knives are famous for - a thin, sharp edge of high hardness inside a softer cladding for strength and flexibility.

Blade steels come in a many forms and in traditional carbon steels it is a compromise between hardness (edge retention) and toughness or flexibility .Japanese blades are often tempered at a higher temperature than in the West resulting in a harder, more brittle edge. This enables a thin, sharp edge and requires a more gentle handling from the chef using the blade than a thicker edged, slightly softer Western chef blade.

Using soft cladding around the hard edge steel increases the toughness of the completed knife, while making the forging process more complex and requiring higher skills than if forging from monosteel.

Directly from Tosa to Sydney

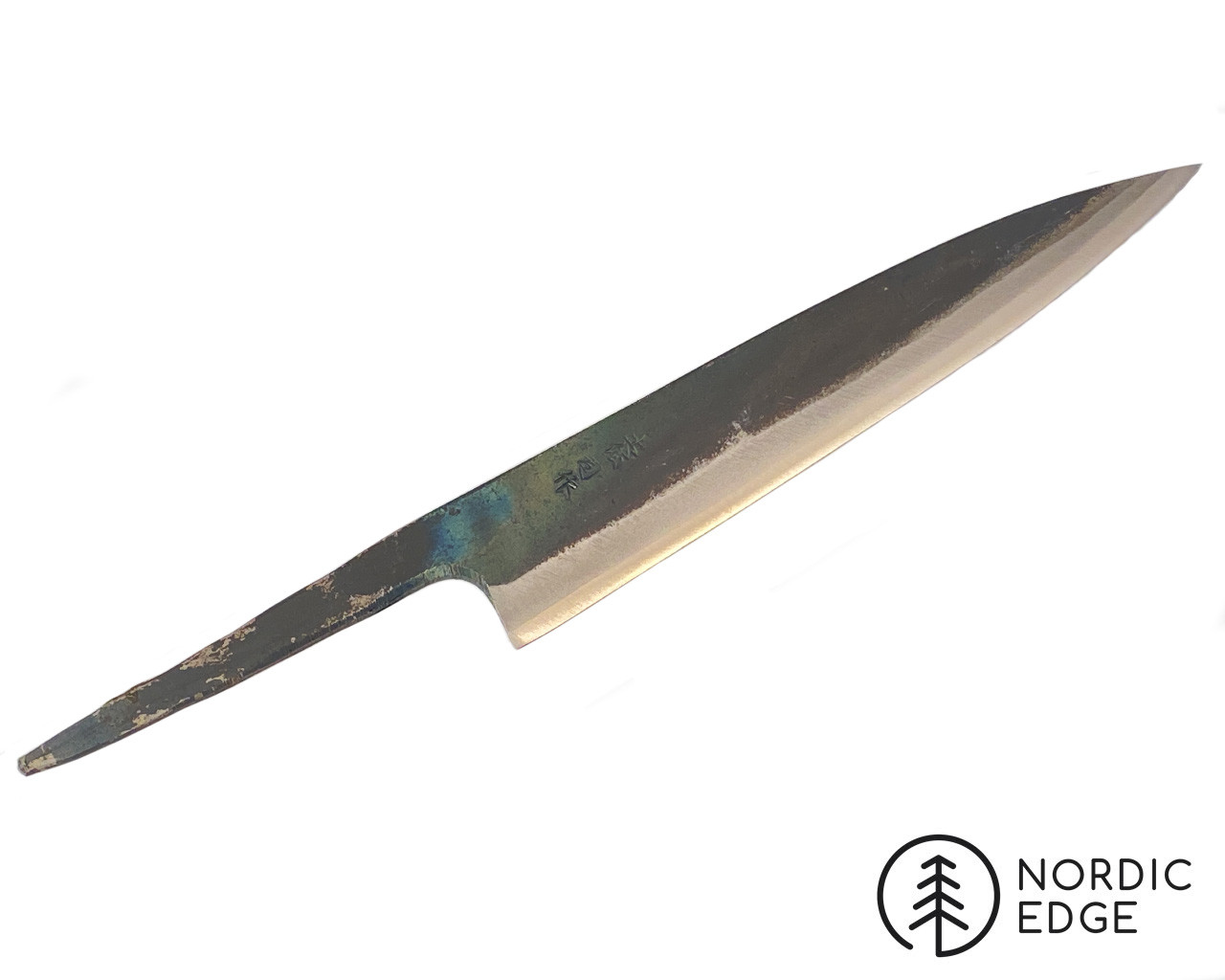

The Tosa blades Nordic Edge has received now in August 2023 are made in this traditional manner, with a combination of power tools and hand tools. The edge steel is White #1, a high-carbon blade steel tempered to a high hardness before being expertly sharpened.

White #1 has a very high carbon content of 1.25-1.35% allowing for a very fin, hard edge. This grade of steel is also known as shiro-ko in Japan and is an advancement on White #2.

The result is a series of knife blades ready for the design and making of your own handle to complete the Japanese chef knife.

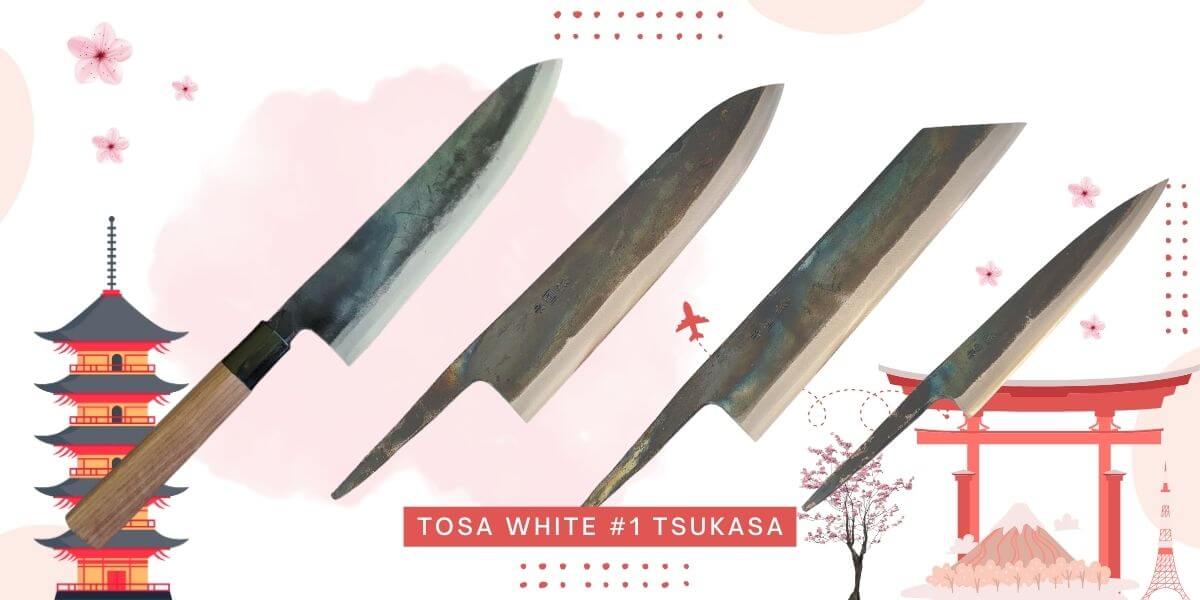

3 Tosa models

The 3 models we have received from Tosa at Nordic Edge now in August are the

- Tosa White #1 Black Gyuto 210 Tsukasa

- Tosa White #1 Black Kiritsuke 210 Tsukasa

- Tosa White #1 Black Yanagiba 150 Tsukasa

Tosa Gyuto 210

Gyuto is a very popular blade style from Japan that did not exist until after WWII, it is the Japanese take on a Western chef knife. Often lighter and thinner edged than the Western counterpart, it is by some considered the "ultimate" Japanese style for it's familiar profile and all-around use.

The blades are sharpened and ready for handle: LINK

Tosa Kiritsuke 210

These are in White steel #1 blade and hand finished with some marks showing the unique blade heritage.

The Kiritsuke style is a bit of an "executive chef" style in Japan, used for thinly slicing fish, vegetables and fruit with a sharp, delicate edge.

The Kiritsuke is easily recognised from the characteristic blade profile, giving it's nickname the "K-tip".

To get your hands on a Kiritsuke for making your own handle, use this LINK

Tosa Yanagiba 150

The Yanagiba is traditionally a longer knife for cutting "wafer thin" slices of fish, here we have a 150 mm version more akin to a paring or petty knife. A very useful companion in any kitchen together with a full-sized 200+ mm bladed Japanese chef knife.

San mai construction with black sides and some marks showing the uniqueness of each blade: LINK

Recent Posts

-

AWARDS 2024: How to Enter & Taking Photos to Score Well

On Wed 15th of May 2024 the live stream was on "How to Enter" and "What Photos to Take" or more impo …16th May 2024 -

1084: The Best Steel Ever?

Is 1084 Really the Best Steel Ever?!Well...it is a good steel, and very popular due to both making a …7th May 2024 -

AWARDS 2024 Kick-Off Presentation Slides

The Australian Knife Making Awards are back for 2024!Wed 1st of May 8 PM AEST your hosts this year R …2nd May 2024