Polar

Nordic Whittling Kit

- Gift wrapping:

- Options available

- default:

- PolarWhittler/SilverBirch/R30/VulcSpacer

Description

Whittler Knife Kit

Make your own version of a classic whittling knife.

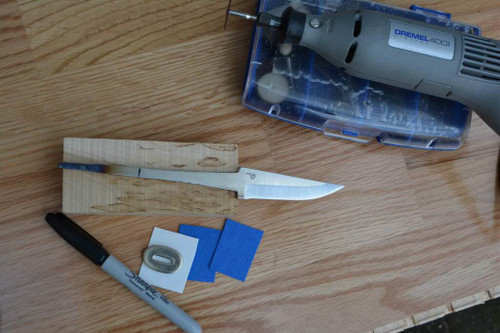

The kit consists of

- Polar Whittler Blade, 80 mm

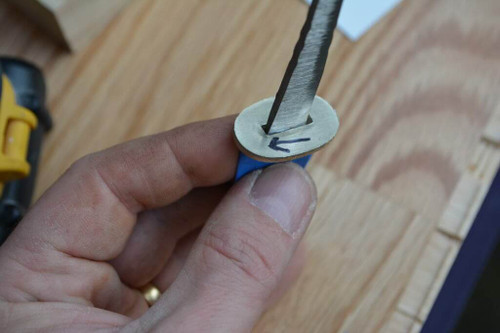

- Metal bolster R30, choice of Brass or Nickel Silver

- Fibre inlay, choice of Red or Black

- Solid wood knife handle block in white Silver Birch (see Options for other woods)

This is a classic Scandinavian knife kit, with a short, sharp blade that gives good grip and power when cutting.

Blade is from Finland, made by Polar in C-0 stainless steel.

The blade is 3 mm thick, about 22 mm high and has about 80 mm of blade.

Total length from tip to end of tang is 204 mm, the tang can be cut to fit the handle.

Customize the kit by selecting the handle material, spacer material and any optional add-ons.

To complete this kit you will need to

- fit the bolster to the tang, with a file or dremel

- cut the tang to size, with a file, hacksaw or dremel

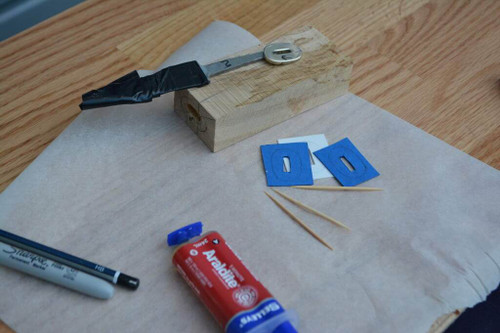

- cut off a piece of the spacer material and drill a hole for the tang

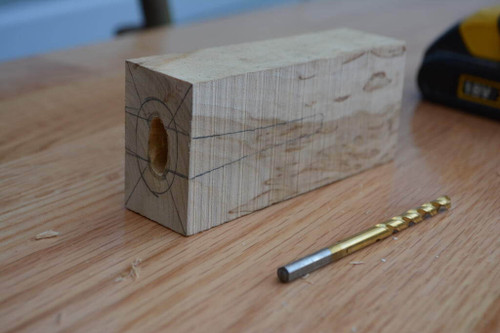

- drill a hole in the wooden block for the tang

- glue blade, bolster, spacer and wood together with epoxy glue

- shape the handle with a rasp, belt sander, or knife

- Smooth the handle with sand paper

- Optional finish: seal the handle with oil, wax or varnish

Example of a Polar Whittler Blade in Silver Birch handle, with blue and white spacers and nickel silver bolster, by Bjorn Jacobsen:

1 Review

-

love it...

So happy with the product and the service. Cant wait to put it together