1084: The Best Steel Ever?

Is 1084 Really the Best Steel Ever?!

Well...it is a good steel, and very popular due to both making a great blade AND being easy to heat treat.

1084 is an old "simple carbon steel" and probably what you were adviced to start with when wanting to make your first knife. Many makers stay with 1084 for decades, it is a popular steel with experienced as well as beginner knife makers. And most (?) damascus makers also use 1084 for the steel that etches dark in their damascus mix.

It is technically not the best steel neither for edge retention or toughness, even though it holds a decent edge and is pretty tough too.

Science today has taken stainless steels way past the "old" simple carbon steels, but 1084 high carbon steel still has an important role to play for knife makers. Due to being easy to work with, easy to heat treat and easy to finish.

Let's have a closer look at this favourite steel of many knife makers..

1084 is a simple carbon steel

1084 high carbon steel has about 0.84% carbon and a few other alloying elements. But part of the reason why it is so attractive to knife makers is that it is in the "goldy locks zone" when it comes to carbon. It has enough carbon to harden fully and hold a good edge but not so much as to require soak times and complicated equipment to harden succesfully.

Succesful heat treatment is critical

Not much else is more important than heat treatment being correct when it comes to how a knife will perform, so this is a pretty big drawcard for makers, both new and experienced. The simple composition of the steel allows for a big window of opportunity for succesful hardening.

Easy to forge

Knife makers making their own blades generally fall into either stock removal or forging (then followed by stock removal). So for many makers it is attractive to work with a steel that allows forging, unlike most if not all stainless steels. Let's agree that is a discussion for another day, for today let us focus on what is easier and less likely to fail and that is where carbon steels rule.

Carbon steels are safer to forge than trying to forge stainless steels, it does not negatively affect the result of later heat treatment and often there is a big window of temperature where the maker can forge to shape without causing issues down the track.

1084 high carbon steel is known as an easy to forge steel, easier than for instance 5160 (leaf spring) and much, much, much easier to forge than say stainless 14C28N if you want to have a play with stainless.

1084 high carbon steel is a very forgiving steel, maybe the most forgiving steel we work with as knife makers. The "forgiving" part simply means the gap for temperature is big and if you get within that window, you will get a good result.

Forging temperature

The hotter you get the steel, the easier it is to shape by hammer.

At some point this becomes too hot, the carbon starts burning out of the steel (sparks literally fly off when taking the steel out of the forge) and you have messed up. Burning off the carbon makes your steel closer to iron, and it will not harden if you keep going. In a solid fuel forge this is easier to mess up than in a gas forge, but you still need to keep an eye on the temperature.

Forging 1084 can be done up to approx 1120 C (2050 F) or so safely, some sources say even a bit higher than that. It is never clever to forge too cold, the best is to stop forging when you no longer see colour in the steel.

Heat treatment is a breeze!

Not this is where 1084 really gets to shine. Heat treatment is critical for how a knife will perform. There are other factors such as blade geometry (cross section of the blade), angle of sharpening, how thin and how tough the blade is compared to the actual cutting task... but heat treatment is often considered the single, most important thing to get right.

So 1084 knife making steel being such a forgiving, easy steel to heat treat is a big drawcard.

Heat treatment can be made very simple:

- heat the steel anyway you can do non-magnetic

- quench in warm canola oil

- temper 2 x 200 C for 2 hours or flame temper (more details later)

At Nordic Edge we are hobby knifemakers and have a bit more equipment than the bare minimum. So we want to do even better than that. Here is what we think is a better heat treatment regime.

Better heat treatment for 1084:

- Normalise by holding blade at 875 C and let air cool x 3

- Hold at 815 C for a couple of minutes (no hold time required, just making sure everyhing really has evened out nicely)

- Quench in a medium-speed quench oil

- Optional cryo : 30 min in kitchen freezer, or dry ice/metho bath for an even better result (read up on Knifesteelnerds on this one)

- Temper at 200 C x 2 hours, cool under the tap and another 2 hours for a good combination of hardness and toughness used in everything from chef knives to outdoor hunting or bushcraft style knives. Should you make a machete from 1084 and want a bit more toughness, temper at 220-230 C.

Other tempering options:

At our workshops we do not have time to do the 2 hours x 2 that is the optimal way. Instead we do "flash tempering" at 250 C for 15 mins x 2, hitting the same point on the hardness curve.

Another, older way of tempering is by colour, we refer to this as flame tempering. The steel blade is ground or sanded to show shiny steel on one side. At least the edge needs to be shiny so you can see the oxide colours forming, but it is easier to get right if sanding the entire side of the blade as you will see the colours earlier.

The hit the back (spine) of the blade with a torch flame, or place it near the heat if using a solid fuel forge until the blade heats up enough to hit temper colous on the edge itself.

By "painting" the spine of the blade with a flame from a gas bottle, moving up and down the blade and focusing a bit more on the ricasso area (more steel to heat up) than the tip, you will after a little while see colours appear on the steel. These are the tempering colours, oxides building up on the steel as it reacts with the oxygen in the air while being heated. When you have tempering colours on the cutting edge (light gold to deep bronze), the spine will be darker, hotter, softer. Many consider this a superior temper due to the softer, springy spine and hard cutting edge.

Easy to finish

1084 knife steel is also fairly easy to finish. You are working hardened steel here, so "easy" might not be the right word. But compared to some steels with more carbides (440C or CPM S35VN) comes to mind, 1084 is a breeze. It grinds well, it sands fairly easy. It takes a great finish, polish and even etches really well.

In the photo above you see two blades forged from 1084. Both were finished on the grinder, no hand sanding involved. They were finished to 600 grit aluminum oxide after being ground on 3M Cubitron 2 belts, before being finished with 3M Scotch Brite belts for a nice, satin machine finish.

The one on the left was left as-is, the one on the right etched. 1084 is easy to etch with ferric chloride for an even, deep etch. The one in the photo was part of an experiment to create a "shipwrecked" finish and had other things done to it after the initial etch, hence the blotched patina. But 1084 is a great steel to use if wanting an etched finish.

Satin finish

Satin hand finish is often done to 600 grit, some makers go one grit progression past 600 and then back to 600 to make sure they have a really uniform scratch pattern.

Comparisons with other common steels

Science has taken knife making steels up to levels not possible in the past, and even as hobby knife makers we today have access to tools and knowledge that was not readily available not that long ago. Particularly the work of people like Dr Larrin Thomas published for free on KnifeSteelNerds and Kevin Cashin on Cashenblades.com (LINK) have done amazing things for the understanding of how to get the best out of the steels available to us.

In that context, where we compare steels to find the "ultimate" steel in a particular criteria, there are now newer, more advanced steels. Steels like stainless 14C28N (link) for instance is a moderately priced, good stainless steel that outclasses 1084 in both toughness and edge retention while also being easy to heat treat (and it is a very popular stainless steel with knife makers).

Carbon steels like the new ApexUltra which is a bit of a carbon "Super Steel" being BOTH tough AND having great edge retention is another example that comes to mind of a steel that will perform even better than 1084 but will be much tougher to finish. It is also a much more expensive steel than 1084. ApexUltra link

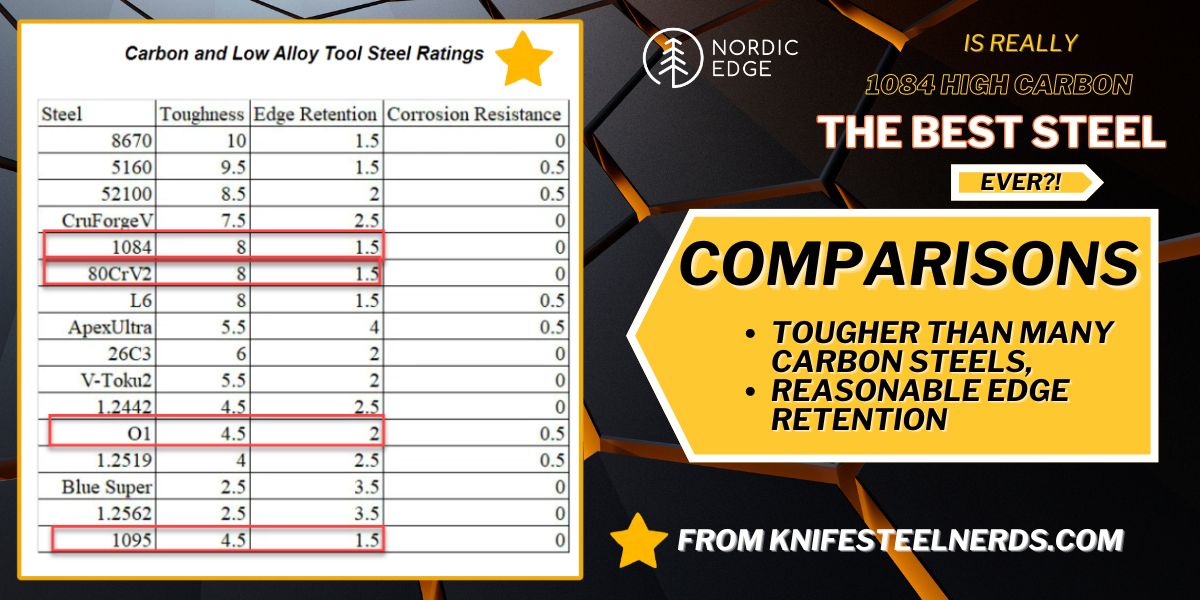

The above table is the work of Dr Larrin Thomas (link to article here LINK) and it is interesting to see how other common carbon steels available to us compare to the trusted old 1084. It is a great read if interested in learning more.

440C is another knife steel that has been around for a long time. Heat treatment of 440C is a bit more complicated with soak times, temperature control required and it is much harder to finish. It holds a better edge but that also makes it a nightmare to hand sand if used to 1084. It is so corrosion resistant (positive) than it is almost impossible to etch evenly though.

AEB-L heat treatment is not too different to 440C also requiring a soak and then ramping to temperature and is another favourite stainless steel of ours at Nordic Edge due to ease of finishing and how even it etches.

80CrV2 carbon steel is often compared to 1084 and considered having a slight edge 1084, while the heat treatment of 80CrV2 is slightly more complex due to the hold time. At a presentation in Australia a few years ago, Kevin Cashen said doing 80CrV2 without the hold time "was like paying for 80CrV2 but getting 1084" so this might not be a steel to pay extra for unless you have the tools to do the recommended optimal heat treatment.

There are so many knife steels available to us hobby makers now and that is great! The point here is not to say steel A is "better" than steel B because different steels perform better or worse at a specific task, in a specific blade geometry and each steel can be heat treated to a range of hardnesses.

Some makers love experimenting with different knife steel types over time, or prefer to make one style of knife in knife steel A and another type of knife in knife steel B. Other makers prefer to find one type of knife steel they like and trust, then work to get the utmost performance out of that particular steel with their particular setup.

Each to their own, the point is more to be aware of the options available to you. And if you select 1084 as your steel, know that you are in good company and it can be a truly good steel to forge, grind, finish - and use!

Conclusion

Overall, 1084 probably outsells any other type of steel for hobby knife makers. At least that is our experience from Nordic Edge in Australia and we have heard similar stories from the US. It is a good steel, you can forge it (which is great fun) and you have a very high rate of success with heat treating in - if you have a fancy kiln, gas forge with or without temperature control (using a magnet instead), or even with a blow torch!

Being so popular, 1084 is readily available in a range of sizes from 2 mm to 40 mm thick: LINK

Recent Posts

-

The Etch Test: Ferric vs Hydrochloric vs Gator Piss

The Etch Test: Three Very Different Looks From One Steel One of the great things about knife making …3rd Jan 2026 -

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025