3M Cubitron II belts - really better than Ceramic belts?!

We are very excited to have 3M Cubitron II belts at Nordic Edge!

Taking over from Ceramic belts

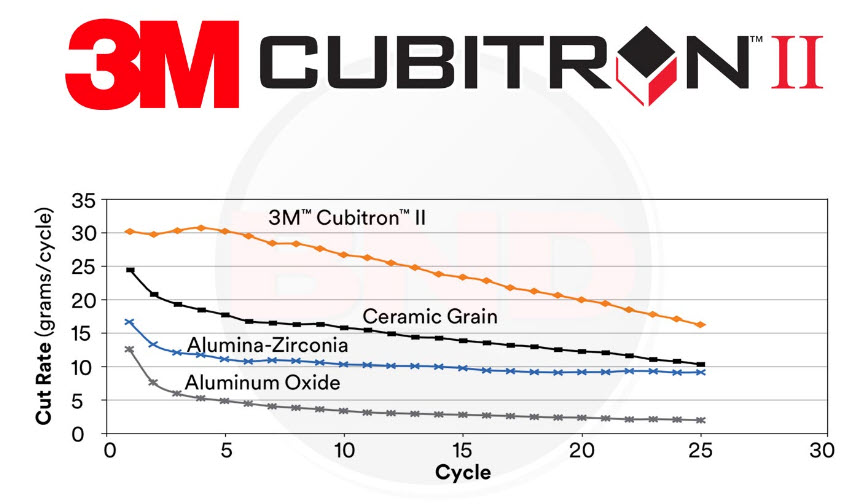

3M Precision-Shaped Grains are the secret behind the success of the Cubitron II belts taking over for traditional ceramic belts. Lasting longer and giving a more even grinding pattern or scratch pattern, these belts are a great fit for knife makers.

The thing to note is that there are different grades of Cubitron II belts - with quite different costs.

- 767F: Recommended for hand grinding, where pressure is applied manually on the grinder like when knife making. These belts have less abrasive and therefore easier to get enough pressure on to continually expose new, sharp grains. These are the ones we recommend for knife making, being cheaper than standard Ceramic belts and longer lasting.

- 984F: The top of the line model more for machine grinding where additional pressure can be applied during grinding for even longer belt-life. These are not usually the first choice for knife making due to the pressure required for max belt life. These are more expensive and still popular with many makers due to being the higher quality abrasive belt.

Ceramic vs Cubitron II?

Where standard ceramic belts use very hard abrasive particles to remove metal and for long life, these particles are not uniform. Meaning there are different sizes, the grains are randomly aligned on the belt and some will be sharp, some dull, some sticking up high and some lying down at any given time. As the belt wears out this difference can get even bigger when some grains come off, dull and glaze over. The result is a long lasting but uneven belt requiring a lot of pressure to expose new, sharp grain surfaces.

With the new Cubitron II technology, each particle segment or mineral is man-made from much-smaller ceramic and alu oxide particles into uniformly sized minerals that are more presicely placed on the belt backing. This means the belt will evenly wear down to always have sharp edges, creating faster grinding and a more uniform scratch pattern for the same job.

The result is cooler, faster grinding and a longer lasting belt!

The below is from 3M regarding the Precision-Shaped Grain technology;

Introducing 3M Precision-Shaped Grain

3M Precision-Shaped Grain is the advanced technology behind our 3M™ Cubitron™ II products. Here’s how it works: Precision-Shaped Grain is designed with sharp, angular structures that continuously fracture to form sharp points.

The Science of Speed.

These clean, sharp points mean an abrasive that slices faster, runs cooler, and lasts much longer than conventional abrasives, which generate excessive heat buildup and have a shorter life. We have observed 3M™ Cubitron™ II products cutting faster and lasting up to 2x longer than some competitive products.

our summary;

our summary;

Nordic Edge is carrying two 3M Cubitron II abrasive belt models, the 767F and the 984F:

- 767F - use this one instead of the older type,standard Ceramic belts. The model recommended for knife making due to cost vs value. They are cheaper, longer lasting and with a more uniform scratch pattern than standard ceramic belts: LINK

- 984F - the "rolls royce" of the Cubitron II range, more abrasive on the belt for even longer life but will require more pressure to continue to wear down new, sharp abrasive surfaces as the belt wears down.: LINK

Recent Posts

-

The Etch Test: Ferric vs Hydrochloric vs Gator Piss

The Etch Test: Three Very Different Looks From One Steel One of the great things about knife making …3rd Jan 2026 -

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025