ApexUltra - how to heat treat the new carbon "super steel"

ApexUltra is a carbon "super steel" developed specifically for kitchen knives.

Tests results are nothing short of impressive:

- High hardness

- Amazing edge retention

- High toughness

What makes the steel so special is the high purity, the low amount of impurities gives less chance for crack formation at a very thin and hard edge as well as the the homogeneity of the steel, meaning it is uniform or very consistent in composition.

The result is a steel that -after tempering - is harder than most other steels before tempering.

A 65 HRC kitchen knife with a super thin edge - that flexes...

Crazy edge retention

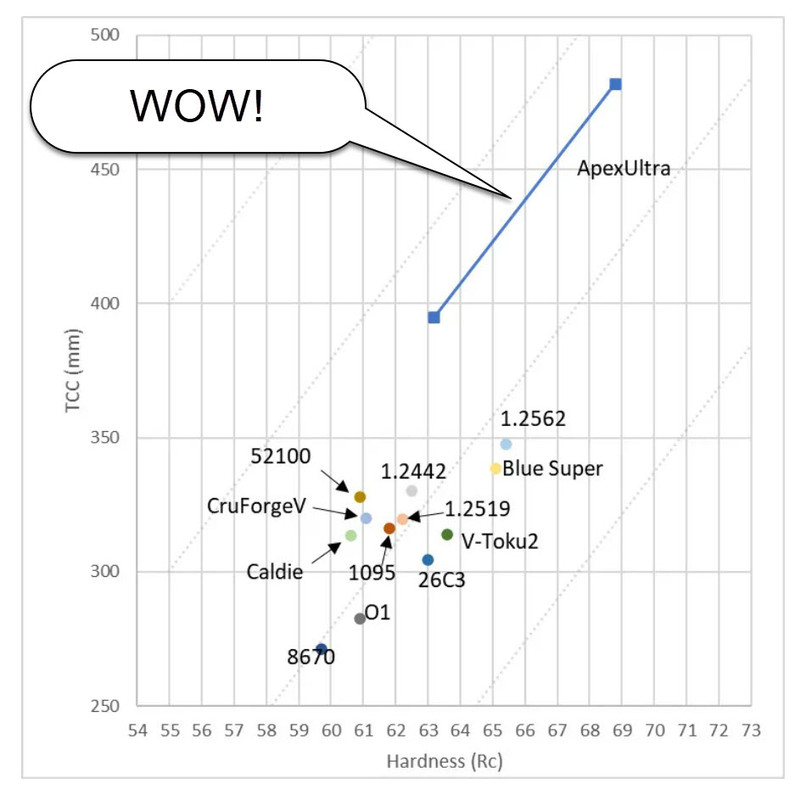

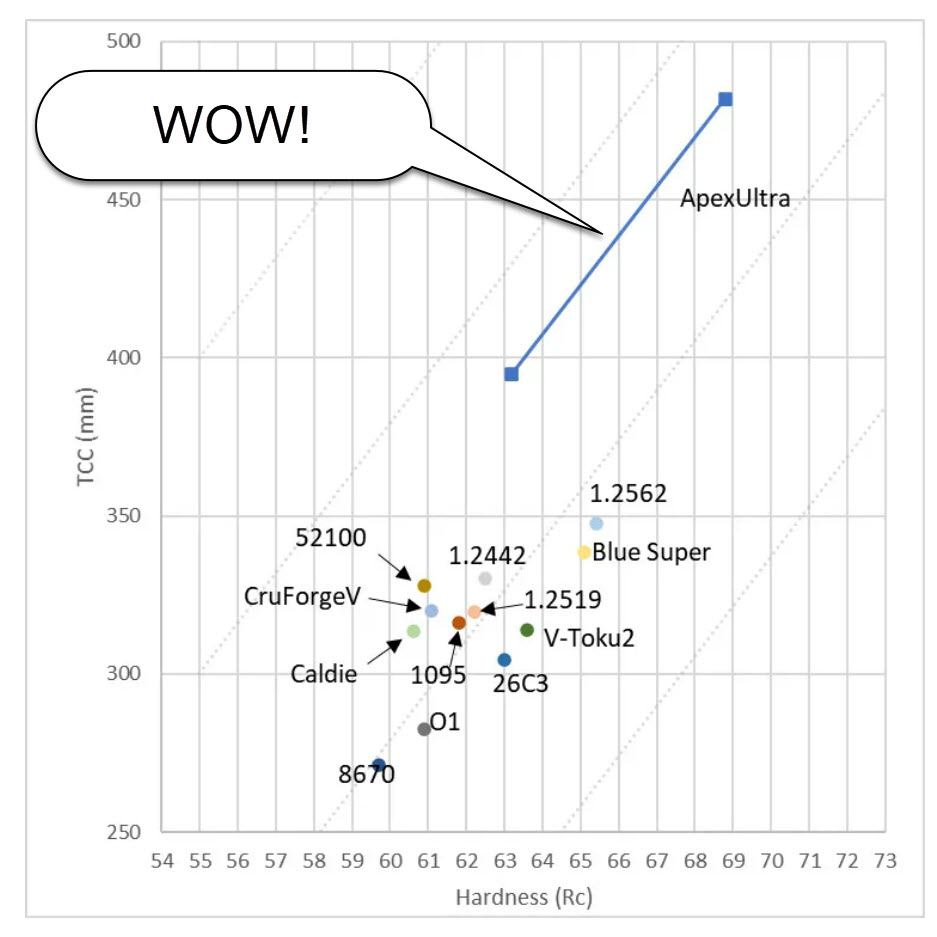

Check out the below graph from extensive edge retention testing by Dr Larrin Thomas at KnifeSteelNerds.com

Then look for 52100 and Blue Super in the lower part of the graph.

Heat treating recipe for ApexUltra:

- Complex steel with several different recipes

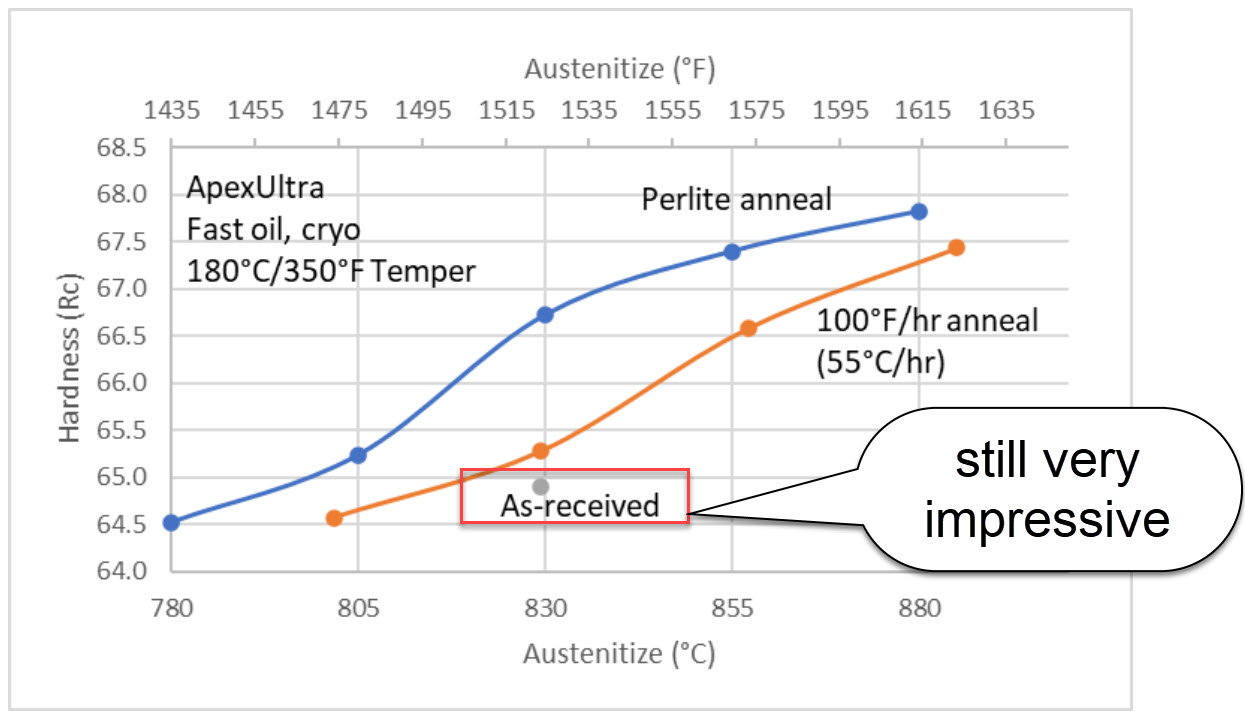

- Annealing speed affects hardness out of quench

- Holding temperature before quench affects hardness achieved

- Below is a good starting point for anneal and hardening, not the only way

Forging temperature:

- Max recommended forging temperature is 1120 C / 2050 F

- Stop forging before the steel looses colour

- Danger: Do not leave sitting around after forging, can partially harden and crack

- Leave in vermiculate to slow cool if not normalising straight away.

Normalising: 2 steps

- Requires higher normalising temperatures due to complex alloy

- 950 C / 1750 F for 15 mins > air cool (even carbide structure)

- 790 C / 1450 F for 10 mins > air cool (refine grain structure)

Annealing: (optional but increased hardness)

- Hold at 790 C / 1450 F for 15-30 min (repeat last normalising temp but slow cool)

- Cool slowly to 590 C / 1100 F

- Air cool is fine from 590 C / 1100 F

- Compromise: Leave in vermiculite with other heated steel bars to slow cooling further for drilling, band sawing*

Hardening / Austenising:

- Hold at 830 C / 1525 F for 10 mins

- Quench in fast or medium speed oil

- Fast oil not required but gives higher final hardness

Cryo / cold treatment:

- Optional step that gives higher hardness of approx 0.5 - 1.0 HRC

- Kitchen freezer 30 min is helpful, dry ice / alcohol bath better, liquid nitrogen best

- do not feel this is required unless chasing optimal mix of high hardness and toughness

Tempering:

- 180 C / 350 F for 2 hours x 2 times for about 65 HRC after tempering

The small text:

This is such a complex knife steel that there is a wide window of possible results.

The very high hardenability is from annealing, higher quench temperature and faster oil.

But even with a medium-speed oil and simpler "950 C > 790 C > air cool" normalising and annealing, very high hardness, toughness and edge retention is achievable.

*Slow cooling in vermiculite or electric kiln is better for drilling or sawing the steel but note this gives slightly lower hardness from quench and tempering due to coarser grains from the slow cooling.

Keep it Simple?

There has been lots of work and tests going into getting the most out of ApexUltra. If you do not do any of these things, but simply harden the steel in the state it arrives - you will still get impressive results around 64 HRC AFTER TEMPERING - do not feel that you need to follow all the steps above to get a good result.

Knife makers often like to tinker, to experiment and to get the max performance out of the materials. This steel is then for you. But you can get excellent results if skipping some of the ultra-high hardness steps and simply heat to 830 C > quench in oil > temper.

For the full version of this article, check out Knife Steel Nerds here: LINK

Recent Posts

-

1084: The Best Steel Ever?

Is 1084 Really the Best Steel Ever?!Well...it is a good steel, and very popular due to both making a …7th May 2024 -

AWARDS 2024 Kick-Off Presentation Slides

The Australian Knife Making Awards are back for 2024!Wed 1st of May 8 PM AEST your hosts this year R …2nd May 2024 -

OPEN FORGE NIGHT Thursday 28th March 2024

Come along to a knife maker meetup at Nordic Edge!Thursday 28th of March 2024 - 5.30 - 8.30 PMForges …27th Mar 2024