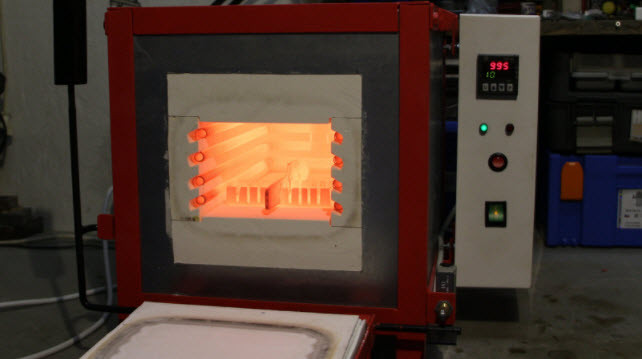

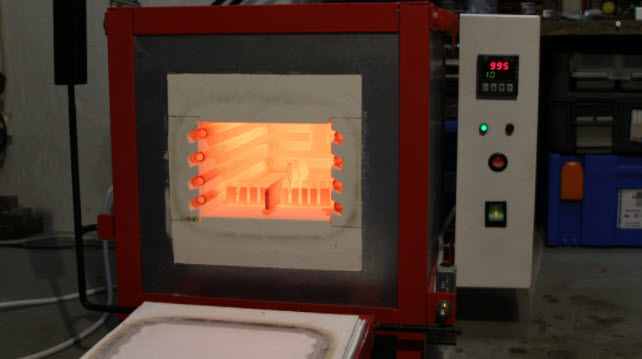

Heat Treating N690 Blade Steel from Bohler Uddeholm

How To Heat Treat N690 to 59-61 HRC:

- Heat to between 649-704 C and hold for 15 min (1200-1300 F)

- Heat to between 815-871 C and hold for 15 min (1500 - 1600 F)

- Heat to 1071 C and hold for 20 min (1960 F)

- Quench rapidly in oil or between plates with compressed air cooling

- Recommended: Cryo treat by deep freezing to -80 C for 2 hours for max hardness (-120 F)

- Temper twice at 185-199 C for 2 hours, for 59-61 HRC (365 - 390 F)

Stainless high-quality steel from Austrian maker Bohler Uddeholm. Complex heat treatment and great edge retention while easy to sharpen and polish. http://creativeman.com.au/n690-stainless-steel-bohler-uddeholm/

Martensitic chromium steel with cobalt, molybdenum and vanadium additions. For tools and components which can be hardened to very high hardness levels. By many compared to VG10 or "Austrian VG10" as a stainless with similar composition and edge retention, ease of polish and sharpening. Used by many commercial folding knife companies such as Spyderco and EnZo, it is considered by many to be easier to sharpen razor sharp than M390 while still having good edge retention. Corrosion resistance is high, with over 17% Chromium.

C: 1.08%, Si: 0.40%, Mn: 0.40%, Cr: 17.30%, Mo: 1.10% , V: 0.1%, Co: 1.5%

The above is our summary from reading this link from Bohler Uddeholm, http://www.bucorp.com/media/KNIFEHEATTREATSUM2.pd...

Recent Posts

-

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025 -

Make Burl Wood POP!

Staining wood with leather dye. or "How to make burl wood really pop". This technique really only wo …8th Mar 2025