How to take your blade design up a notch: Better Knife Design

How to design better looking blades?

- focus on one area to improve on at a time

- study profiles / templates you like

- break down the design to understand why you like it

- blade length and height

- ratio of blade:handle

- ricasso height vs width

- straight spine vs curved

- tip profile

- handle height and length

- flowing lines or strong, aggressive turns

- use a template

- save your work (templates)

Focus on one area at the time:

A good technique for improving skills in an area is to try simplifying other areas of the process, to be able to really focus your efforts into lifting your game in the area you are working on.

Many makers will for instance improve their grinding game by making the same blade again and again, allowing muscle memory to build up. As well as when focusing on fewer moving parts, you start noticing the small things and how they affect the final result.

Knife design is another area where this is true; find a style you enjoy and make it again and again. This will really assist in increasing your skills on grinding as well as fit and finish as you get time to really nail the detail. As opposed to switching styles for every knife.

Heat treatment is another area that springs to mind; experienced makers in the Australian Knifemakers Guild often recommend to new members to find a steel they like - and stick to it.

Knife design is no different, simplify the process by repeating what you are doing to really learn it. and learn from others by using or copying a design you really like, then break down why you like it to try making it even better.

Start with a good-looking design:

We all love most if not all knives we have made ourselves, this is only natural. But to make a result that another maker -or customer- will pick up and appreciate is a harder goal and requires both good design and good execution.

To deliver a good looking result, using templates is another tool of the trade. Assuming you start with a good template, lines tend to flow better than if just free-handing a drawing with a sharpie on the length of 1084!

If knife design can be broken down into levels, these might be it;

- freehand / no design "I take the steel where it wants to go"

- hand drawn design on paper (great results, takes time to learn to do well)

- ready-made templates (good result but you may over time want to make your own)

- Computer-aided Design (CAD) (excellent results but harder again to learn)

** Disclaimer: there is nothing wrong with free-handing a design. We just don't think this is where you should start as many makers end up with a profile that is not reflecting of their best work when free-handing **

Hand-drawing is where most or all of us start out and many become amazing at it. Personally I am not great at drawing and found a set of French Curves to be a great help. This is a tip from Karim Haddad of Tharwa Valley Forge, "every curve on your knife you should be able to find on a french curve".

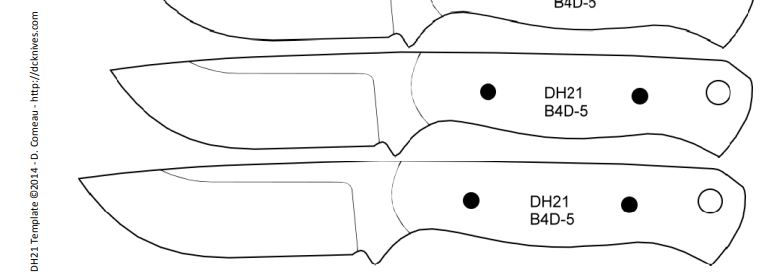

Ready-made templates: DCKnives.blogspot.com

Starting with a good-looking template from the style you want to make is a good idea, enabling you to spend the time improving your game and knowing the result will look symmetrical. DC Knives is a great resource to our field, check out the massive amounts of templates on offer (He says they are free but if you end up using them, send him a beer or something). When wanting to make a new style of knife, this is highly recommended as you will make a knife that is good-looking and you can use this as a starting point for your own design.

CAD templates:

If you really want to pick up your game, check out KnifePrint.com

This is a custom made CAD software for knifemakers. It comes with templates you can start from and customise, or you start from scratch.

The point is that this is a quick way to for instance print your design with 5 different tip designs, or 3 different handle options.

CAD work is usually a tool for folder makers and others wanting a high level of precision but we have found Knifeprint.com to be fun to play with and easy enough to learn.

If wanting to check it out, using the below link gives CreativeMan.com.au a cut without costing you any extra: https://www.knifeprint.com/u/vbhnp

Kevin Slattery from Kev's Forge was one of the pro presenters at the 2020 Australian Blade Symposium, delivering a session on knife design. Kev is big on spending the time required to create a functional and good-looking design and then saving it for the future. As a full-time knife maker and teacher at Kev's Forge in Canberra, Kev wants to benefit from the work that went into the design more than once, and he has recently taken up Knifeprint.com as a way to quickly proto-type different designs and giving his clients freedom to design their own work.

Maybe more a tip for the pro makers but a CAD solution is a quicker way to get a good looking design when taking a new client brief as well.

Save your work:

However you make your design, you should make a solid template for next time. How many of us have tried to recreate a knife that really worked out well from a poor sketch or memory. When a template cut out in stiff plastic or thin plywood would been a lifesaver. The lesson is simple, save your work for the future. You might end up saying you want "the handle from that one" but the blade of another.

And last but not least: Hold it to the light

A great tip from Ian Stewart from Two Feathers Forge, is to always hold the blade up against the light to study the lines. Nothing will make a small issue pop out at you as 30 seconds of looking at a profile of your blade or knife.

d

Recent Posts

-

The Etch Test: Ferric vs Hydrochloric vs Gator Piss

The Etch Test: Three Very Different Looks From One Steel One of the great things about knife making …3rd Jan 2026 -

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025