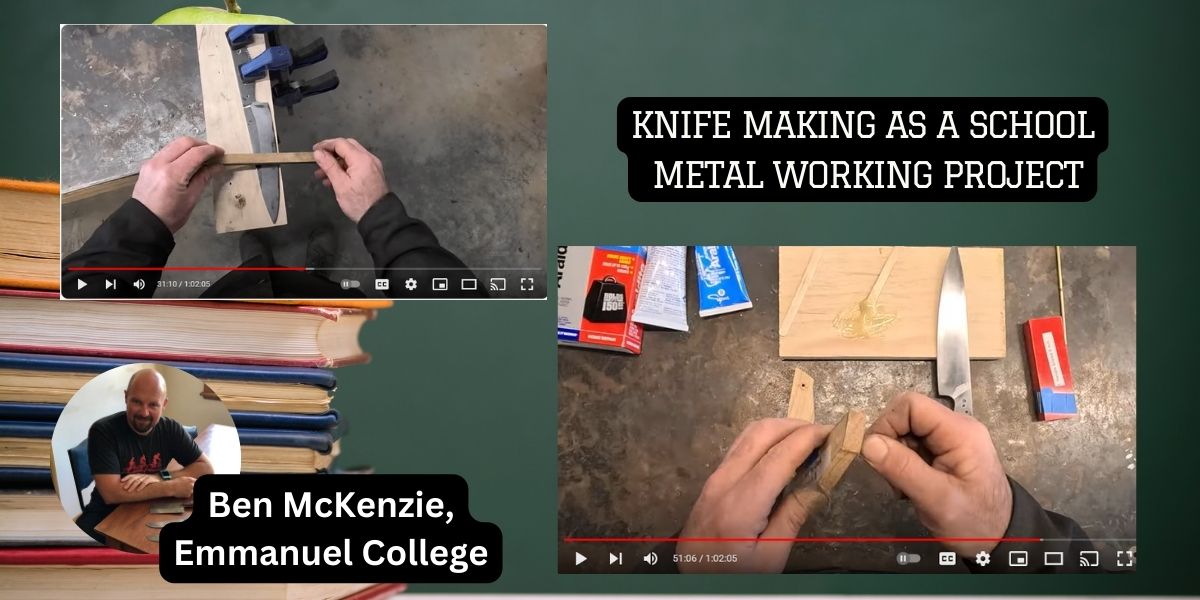

Tutorial: Knife Making As A High School Metal Working Project

Ben McKenzie is the Design & Technology Coordinator with Emmanuel College Warrnambool in Victoria, and Ben has kindly sent us the link to his tutorial video on how his college runs knife making as a metal working project in high school.

"Finding challenging models that cover the curriculum and inspire the kids, gives me a lot of satisfaction.

And bringing knife making to the classroom has been one of the most fulfilling projects to date."

Ben in his Meet The Maker Interview back in 2019 (LINK)

Tapping into the students creativity

Ben is passionate about the students making something they will be excited about using for years to come, and his class has become very popular with the students and parents at Emmanuel College. By making something as practical as a chef knife, the students learn about metal working, using tools and applying patience as well as getting to see the result of their hard work. Many of the students have expressed that the chef knife was a gift for their parents, and something they were very proud to have made themselves.

Parents need to collect the knife at school

Each student is allowed -with parental permission - to make their own chef knife during the semester, hand filing the blade and making the handle to their own design. Then when the project is completed, the parents can come to school and pick up the completed chef knife to take home.

Other teachers wanting to take part

Since Ben started this projecta few years ago, he has been contacted by other teachers wanting to roll out the program at their schools, and Ben has been happy to share what they do at Emmanuel College.

Making the tutorial video

Because Ben was contacted by other teaching institutions about how to safely and succesfully run his program, he has kindly put together a video showing in detail how the chef knife comes together, with tools available to most metal working shops in a high school setting - with a couple of exceptions like a gas forge and tongs.

A great introduction into knife making

The video is well-made, clearly showing the steps involved, the tools and techniques used and also covers sourcing materials, dimensions and materials for the hand-filing jig and other aspects valuable to someone making their first knife. The video is a great resource for anyone wanting to make their first knife at home, also outside of an educational environment.

Moosehead Forges

Les Batchelor from Moosehead Forges was someone Ben leaned on early in the process, helping with adapting the process to scale out into a group of students in a safe and educational way. Les provided the forge used for heat treatment and assisted with several of the early sessions. (Editor's note, the forges we use at Nordic Edge are all from Moosehead Forges, they are great: LINK)

For the full video with all steps, see link below going to Youtube:

Thank you Ben for sharing the teacher's tutorial with us!

Nordic Edge are very happy to supply the materials Ben is using in the video;

- 1084 high carbon steel in 3.5 x 38 x 900 or 3.5 x 50 x 900 mm (width of blade)

- Handle scales in wood, micarta and G10

- Handle pins in brass, copper or stainless steel

Recent Posts

-

The Etch Test: Ferric vs Hydrochloric vs Gator Piss

The Etch Test: Three Very Different Looks From One Steel One of the great things about knife making …3rd Jan 2026 -

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025