Blacksmith Workshop: Making a Chef Knife in a day (Sydney)

Blacksmith Workshop: Making a Chef Knife

We have been having fun working on the format of the blacksmithing workshop, after feedback from students. Some student wished they had been making chef knives rather than the more blacksmith-looking "herb chopper" or pizza cutter.

So we stuck our heads together and got some awesome process advice from Kevin Slattery of Kev's Forge (who hold workshops in Canberra) and changed the workshop to this;

- Forge a chef blade from 1084 High-carbon steel by

- use 3.5 mm thick steel rather than 6 mm

- start with a pre-shape to save some time on extending the tang

- Draw out the tang to 20 x 80-120 mm

- Texture the top half or add some distal tape

- Hammer the bevels in which creates the edge and lifts the tip

- Normalise x 3 times to stress-relieve the blade

- Heat treat the blade by heating to 815 C and rapidly quenching it

- We help temper and grind the tang while the students have lunch

- Grind the bevels and clean up the blade

- Use pre-made handles to speed up the handle fitting

- Sharpen the chef knife

This way we are able to make a chef knife in a single day a

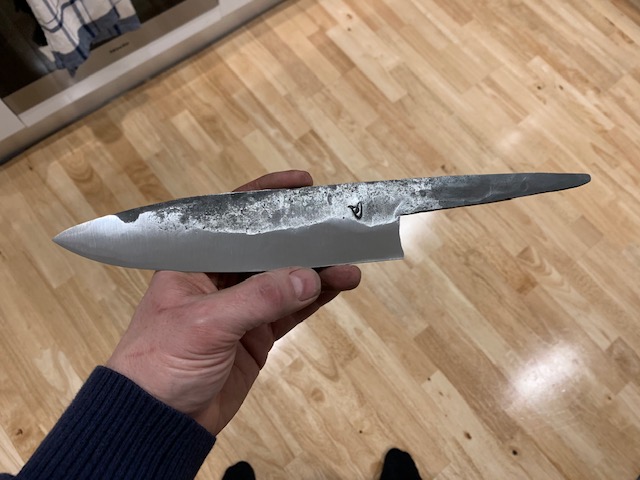

Some photos of the process below

In this photo the blade is not epoxied into the handle, but I am sure you get the idea :)

If wanting to do the blacksmith workshop, you can book into one our small group workshops here: https://creativeman.com.au/blacksmithing-workshop-sydney/

Or if booking all three spots on the workshop, you can have it as a private event most any Sunday as long as we get a few days to set it up by emailing us on the ContactUs page https://creativeman.com.au/contact-us/

Recent Posts

-

The Etch Test: Ferric vs Hydrochloric vs Gator Piss

The Etch Test: Three Very Different Looks From One Steel One of the great things about knife making …3rd Jan 2026 -

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025