Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"?

Bedding the tang means gluing a stick-tang blade into the handle block in such a way that it can come off again to be shaped without the blade in the way.

The advantage is that the "hole" left in the glue now perfectly fits the tang. So when shaping the handle, you know it will go back on exactly right. As opposed to moving slightly in an oversided hole and the handle centreline not aligning with the spine and edge of the blade.

Is it necessary to bed the tang?

Absolutely not. Consider this a bit of an "advanced" technique to play with after a while, if you feel the need. The easiest way to shape the handle and know the centreline you draw on will forever match the spine of the blade - is simply to glue the blade in and shape it after the glue has set.

This is a great starting point and what we all do to begin with. The main reason to ever look at bedding the tang -as far as we know - is in case you want the freedom to shape the handle off the blade. And know that it will fit perfectly back on later.

So if in doubt, stay with epoxying on the blade and then worry about shaping the handle later with the blade in.

What is the point?

The big advantage in bedding the tang and then knocking the handle block off again, is that you have the freedom to shape and sand the handle without the blade in the way.

How many times have you shaped the handle block and touched the blade to the belt? Or struggled getting proper access on the disk or belt grinder due to the blade being in the way?!

Sanded the handle and scratched the beautifully etched blade..

This is the beaty of bedding the tang, you end up with a handle that you can put on and off the tang. Draw lines, make sure everything lines up, then take it off the blade and go grind again..

Etched blades - etch after the handle is done

Another advantage is that this way you can completely finish the handle and then go etch the blade when done - off the handle.

Rather than try to delicately handle the etched blade without rubbing something off or placing it down on something and scratching it.

You can leave the final finish sanding to after the blade is done as well, then etch the blade and it will still fit perfectly into the completed handle. (sand to 320 grit, make the handle, then come back and finish hand sanding)

How to Bed the Tang

The process can be a bit nerve wracking the first time, worrying about the tang coming back out again. There is nothing to worry about. If you do a too good job gluing in the blade and cannot get it back out, just shape the handle on the blade like you would normally do!

Steps

- Fit the blade to the guard or bolster or front handle piece completely, whatever you are using as the first piece touching the handle.

- Grind the tang so it tapers towards the end with smooth, even sides. 60 grit is enough, just make sure it tapers towards the end both in profile and seen from the spine.

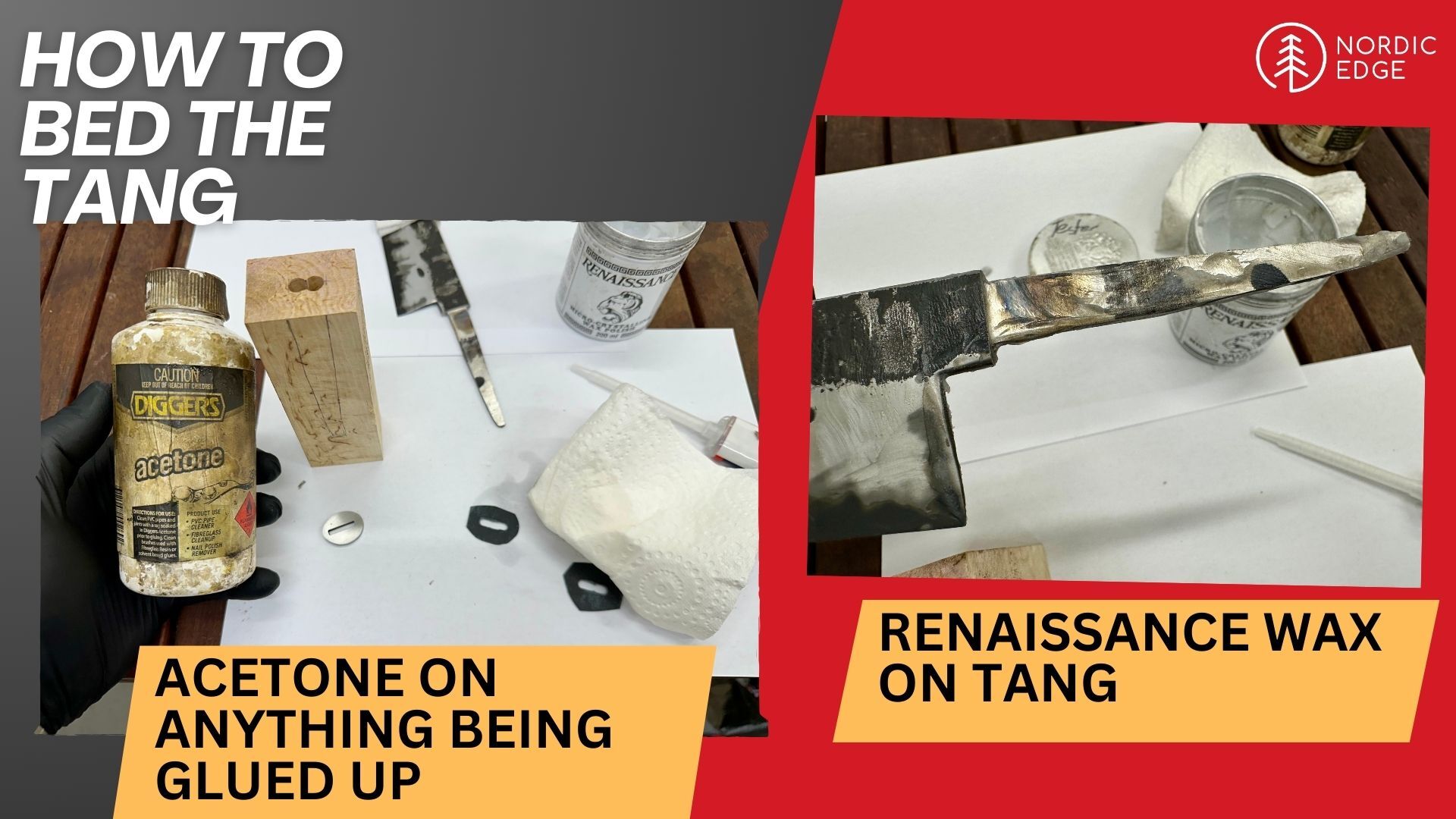

- Wipe all parts that are being glued together with aceton like normal

- Apply a thick layer of Renassaince Wax* to the tang and ricasso of the blade (anything not being glued in that might touch glue)

- Add some Ren Wax to the front of the guard as well, trying to not get anything down into the handle slit.

- Glue up like normal with G/Flex or 5-min epoxy

- If using 5-min epoxy, hold blade in block for a couple of minutes until it sets. Clamping is even better.

- When the glue has set, knock the handle off.

- Rasp with a broach in the handle hole to create a touch of space to be able to get the tang all the way back in.

- If needed, grind very lightly on the tang, don't go overboard as this removes the tight fit that is the entire point of this process.

*Other wax will probably work just as well. Master Bladesmith Jackson Rumble told us he is using Renaissance Wax so that is what we are going with too as we always have it in the shop for final blade protection anyway.

But will the glue stick to the blade now?

A concern we had when playing with this the first couple of times was that wax residue would be left in the tang slot and the blade would not glue in properly the second time. This does not seem to cause any issues, the Ren Wax sets hard on the tang and pulls out with the tang, it seems. (Will this work as well with other wax that does not set hard within a couple of minutes? Not sure)

How long to wait before knocking it off again?

The first couple of times we left 5-min epoxy for 30 mins or something, this was too short. When knocking off the handle block, the glue was set but not completely. So some of the glue was pulled into the tang hole - then it set.. So a lot of rasping with a broach and file was necessary before the tang would go back in.

Now we use 5-min epoxy and then let it set completely overnight. The Renassaince Wax makes sure the handle block comes off cleanly the next day anyway. Overnight is probably overkill, an hour or two probably works just as well.

How to get the tang back out

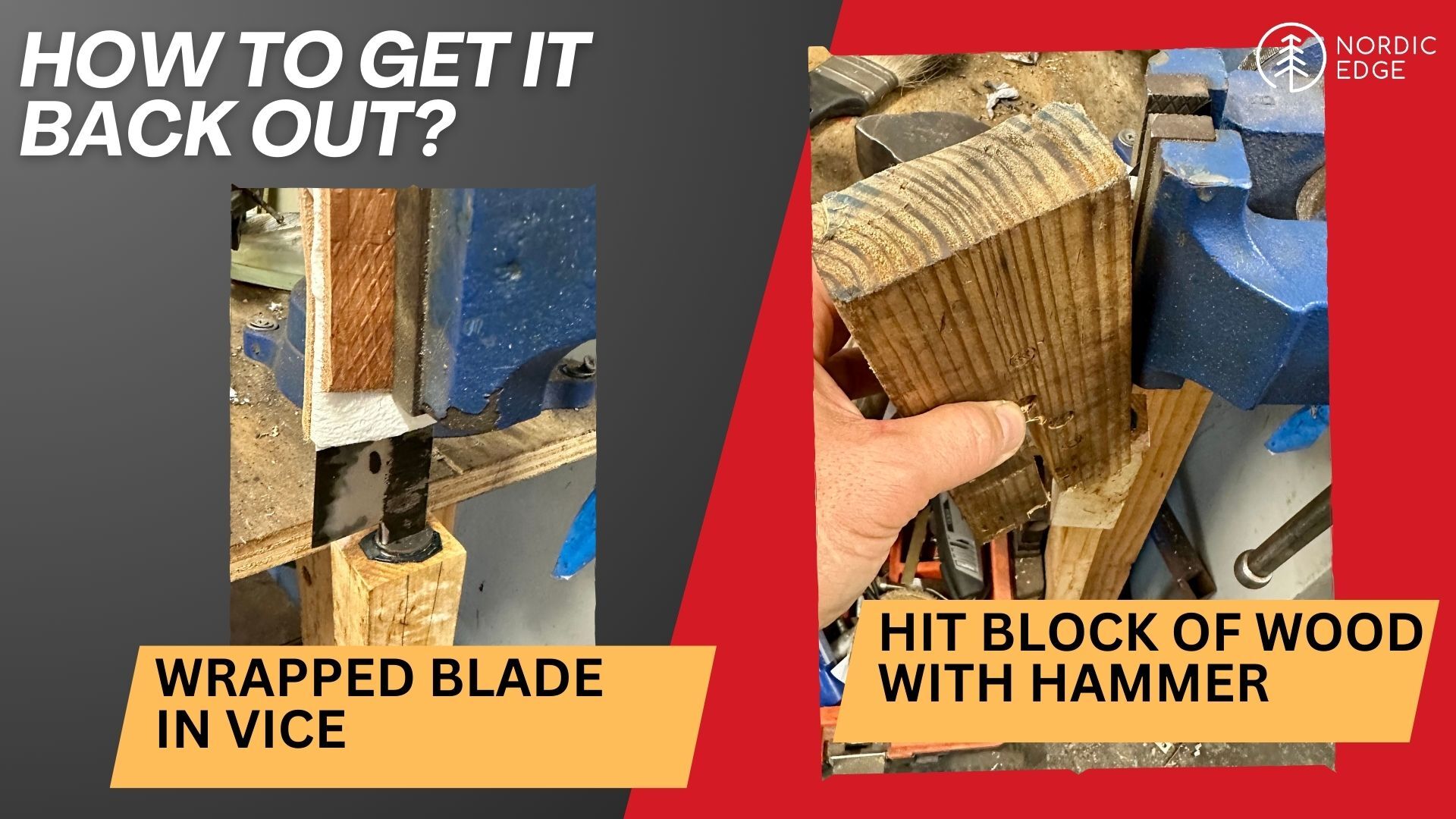

When it is time to get the tang back out of the handle block, the easiest is to use a vice and a block of wood.

If the handle block is in many parts, you might want to tape the whole block together to give it some extra strength to hold it together when being banged on.

For a simple one piece of wood like this knife there is no point taping it, just whack away at it.

Steps:

- Wrap the blade in some kitchen paper

- Wrap some leather around this to make sure the vice jaws do not scratch the blade

- Clamp blade securely in the vice with as easy access to the blade/block transision as possible

- Place block of wood on the handle and hit it with a hammer.

- A short, sharp blow is better than careful little hits as you want to get it cleanly off.

- If able to use a block with a slit in, so it goes on both sides - even better!

- Place something underneath to catch the block in case it comes flying off and cracks on the floor if fragile

Fit the tang back in

There is a little bit of work before the tang will fit perfectly back into the handle hole it came out of. We usually have to use a broach and rasp off a little bit of the sides. Then using a thin wood rasp, we touch up the flats as little as possible to get the tang all the way back in.

A couple of times we have had to lightly grind the tang (and make it 5 mm shorter) before it would go in nicely.

Some like to burn the tang back in but be warned - this smells pretty bad and we are not doing that again!

Now for the fun part!

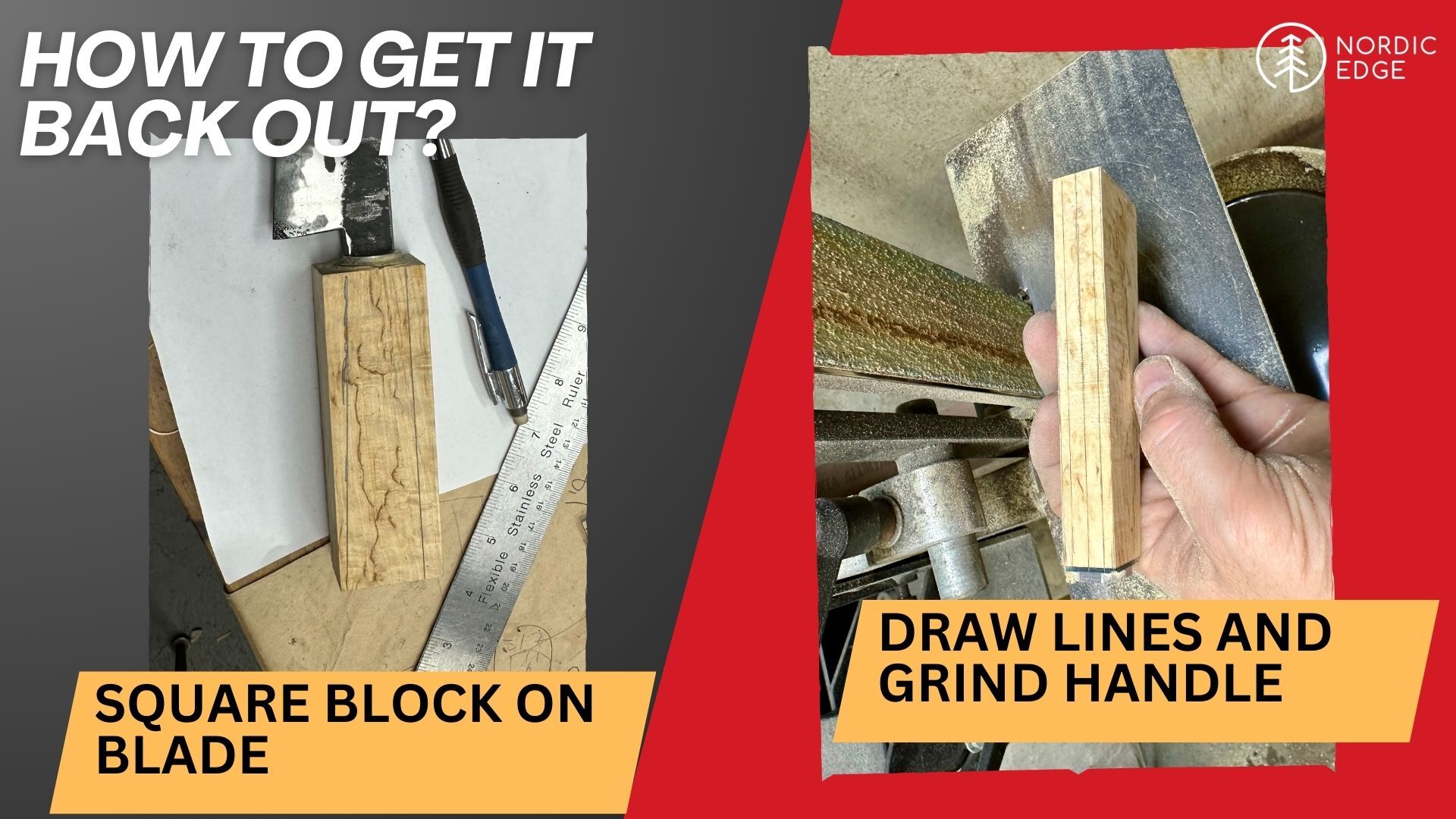

When the tang fits all the way back in, the fun part starts. You can now draw the centreline on top and bottom of the block and the outside measurement (12 mm for instance) on each side of the centreline.

Go grind to these outside lines and you now have a block which is perfectly centered on the blade with square, even sides (in this case 12 mm on each side of the centreline).

This step is soo much easier if having a surface plate and height gauge but can be done with just a ruler and pencil.

Handle shaping process

There are lots of ways to do this, the below is what was done to the handle in these photos:

- Square blade on block, grinding to the marked lines then squaring block on disc grinder

- Draw on profile, spine line is to flow into handle. Ricasso line into underside of finished handle.

- Try to make any step up/down small where the line meets the handle.

- If drilling and adding any pins, do this now as you have a block with parallell sides still, with the correct profile/side view.

- Taper block from spine view (say 16 at front and 22 mm at back) - in this case we went for a uniform 16 mm front to back but normally we would taper it a bit

- Square > Profile > Taper

- Then draw on final lines for rounding corners, adding bevels or whatever else you are doing to the handle.

- The fact that the block is square and symmetrical on the blade makes this process so much easier and more enjoyable!

Finish the blade

If the blade was not 100% sanded ready due to worrying about it being scratched while taking it in and out of the handle, this is the time. If it needs to be etched, this is the time as well.

Complete the blade, knowing the only step left is gluing it in. Etching it without worrying about the effect on the handle is so much easier too.

Glue the blade back in

When the handle is shaped, sanded and possibly also sealed with UBHF, we glue the blade back in.

This time it takes very little glue so go light on the epoxy and be ready to wipe as it comes back up.

Congratulations - you have bedded your first tang!

Is tang bedding worth it?

In our opinion, bedding the tang is not that much more work. And the actual handle shaping is more fun as well as easier. AND we get to clean up the blade with final sanding and etching without worrying about the handle. Working with the disc grinder on slow speed, grinding exactly to the pencil lines with no blade in the way is probably one of the best parts of knife making. Try it once and you might be hooked too!

Recent Posts

-

The Etch Test: Ferric vs Hydrochloric vs Gator Piss

The Etch Test: Three Very Different Looks From One Steel One of the great things about knife making …3rd Jan 2026 -

Why Bed The Tang In Epoxy - Then Knock it OFF Again.

What is "Bedding the tang"? Bedding the tang means gluing a stick-tang blade into the handle block i …21st Mar 2025 -

Marble Leather - How to Dip Dye Veg Tanned Leather

This was my first experiment with hydrodipping or dip dying leather, and it came out pretty cool! I …14th Mar 2025