Description

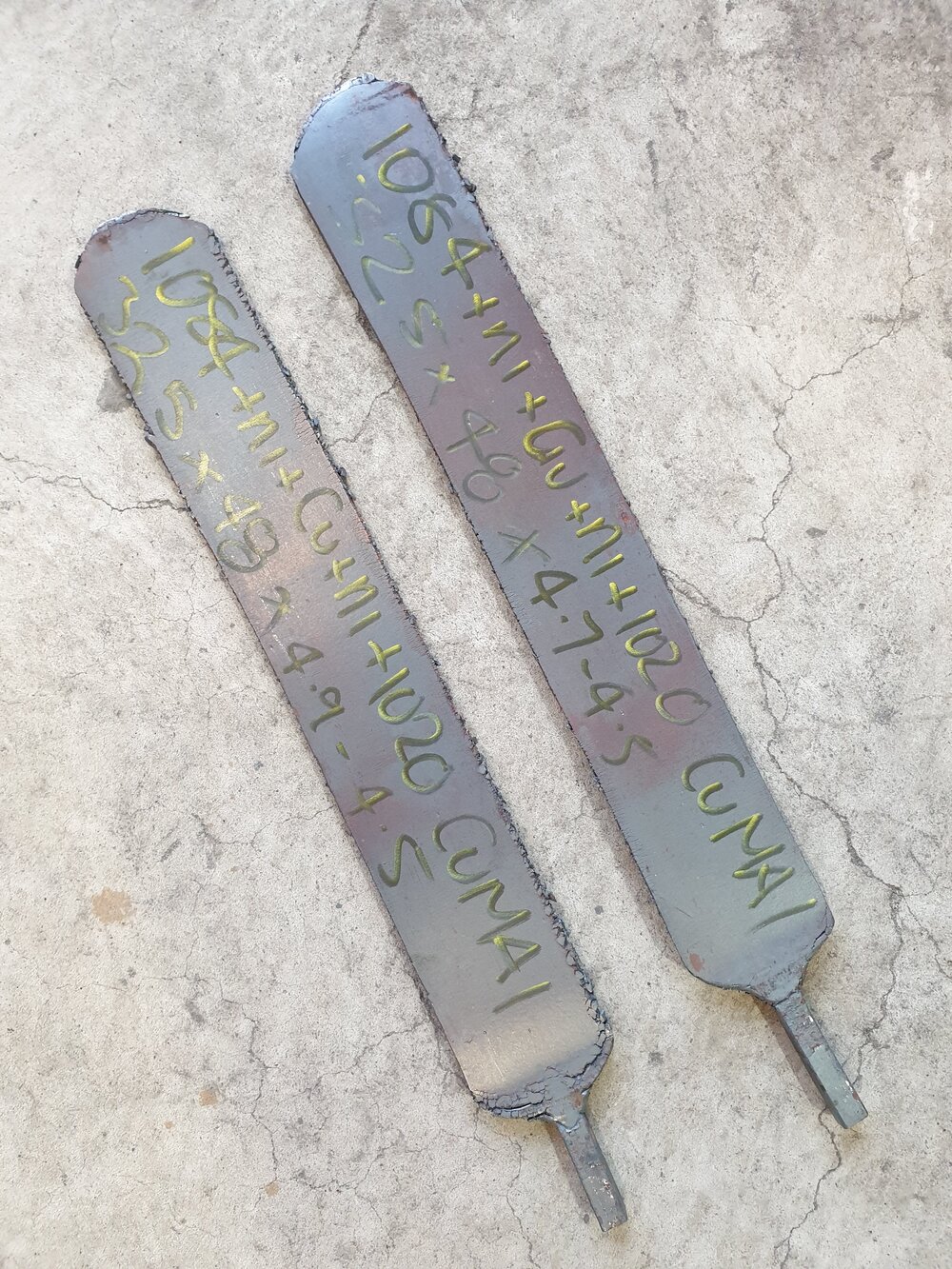

How to Heat Treat Cu Mai (1084 + Nickel + Copper + 1020)

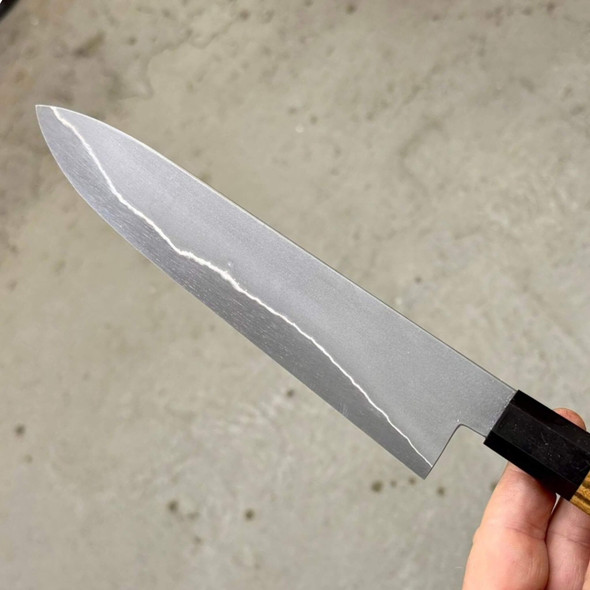

Cu Mai is an amazing-looking material in the right hands, but certainly not a beginner project.

The laminated copper in between the steel and nickel makes it temperamental, and will require some experimentation but this is the recipe Jezz at Oblivion Blades succesfully use. He should know, he has made every bar we sell.

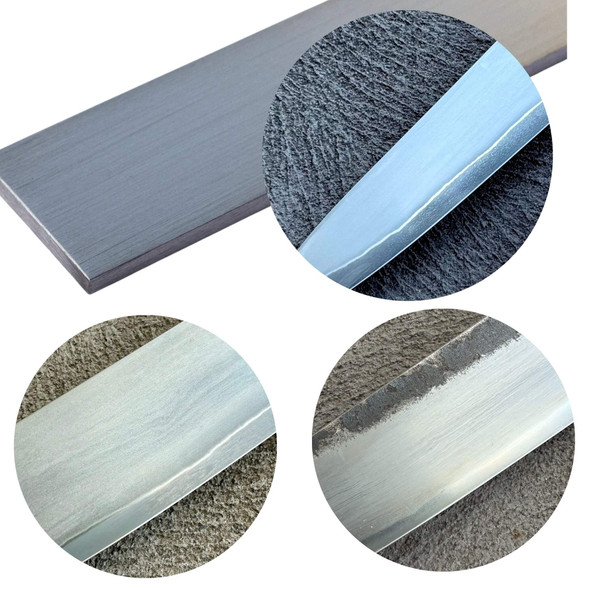

The Cu Mai consists of 9 layers:

- 1020 Mild steel

- Nickel

- Copper

- Nickel

- 1084 High Carbon steel

- Nickel

- Copper

- Nickel

- 1020 Mild steel

The nickel helps with the welding of the different materials, as well as give a shiny, attractive line in the etched steel.

How to treat Cu Mai with 1084 core:

- 865 C with 5 min hold time

- 815 C with 5 min hold time

- 750 C with 5 min hold time

- 820 C with 5 min hold time

- Quench in Houghton's fast oil at 40 C or Canola oil at 60 C

- Temper at 200 C for 2 hours x 2 times

Optional steps:

Annealing:

Heat to 825 C and cool at a rate not exceeding 30 C /hour in a kiln.

Bringing it to temp and leaving in a gas forge with the doors shut until cool will also provide an okish result if no kiln is available.

Forging: DO NOT HEAT ABOVE THE MELTING POINT OF COPPER 1050 C.

For best results, keep the bar under 1000 C and forge in short intervals, going hotter when having more experience with the Cu Mai material.

Texturing: Can easily be done cold and yields good, consistent results.

Straightening: Can be done cold by hammering.

Other considerations: If you get the Cu Mai to hot, you run the risk of copper induced hot shorting. And if you hit it, and it feels like an inside-out cheese toastie - you are too hot and about to melt the copper.

Jezz, Oblivion Blades

NOTICE: This is not a steel for beginners. There are no refunds for messing up these by forging them or heat treating them. This is a risky product for higher level makers who accept the risks involved in a product that consisting of high carbon steel, nickel and copper... be warned.

Pro Tip: Don't grind these before heat treat. Flatten, profile but don't grind bevel. As the cheeks are not hardenable, there is no advantage to grinding profiles before heat treat. This only increases the chances of warping or issues during the heat treatment.