Oblivion

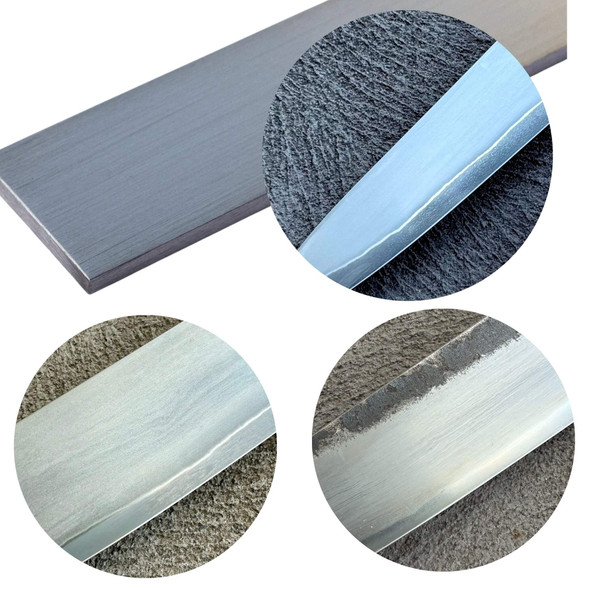

San Mai Billets: Aogami Super Carbon Steel, Nickel, Iron Cheeks

- Gift wrapping:

- Options available

Description

San Mai Billets from Oblivion Blades, Made in Australia

These are made to be forged or at least flattened by hammer, and are as such not flat as monosteel bar stock.

The billets are made by Jerarmie Heywood from Oblivion Blades who is well-known not only for his knives but for his specialty steels.

We are lucky enough to get some of these bars in the top steel Aogami Super Carbon, capable of high hardness.

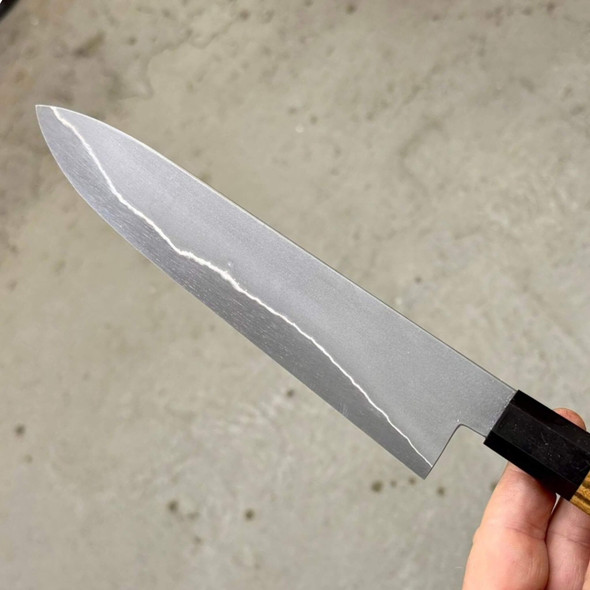

This one is Japanese "super steel" Aogami Super Carbon with mild iron cheeks, and pure nickel as a shiny layer inbetween. This creates a stunning looking blade when ground and etched.

As each is hand made they are different in size but weight is about the same, roughly 550-700 grams.

The size is from 400-500 in length, from 50-65 in width and 3-4.5 mm in thickness to be forged to final shape or thickness.

Jerarmie has made a name for himself with custom billets of Japanese steels clad with nickel and mild steel, this is it.

Aogami Super is a steel from Japan, this is what JapaneseChefKnives.com has to say about the steel;

"Aogami Super (Hitachi Metals Ltd.) is one of the greatest Japanese Carbon Steels. In addition to containing more Carbon, Chromium and Tungsten than Blue Steel No.1, it also includes Molybdenum. It has very good edge sharpness and excellent edge retention, but is also capable of attaining high hardness without being brittle. Consequently, many knife enthusiasts rate Aogami Super as one of the very best High Carbon Steels in the world.

"

Note the ultra high carbon content:

C 1.40-1.50 % | Cr 0.3-0.5 % | W 2.0-2.5 % | Mo 0.30-0.50 % | V 0.5 %

NOTICE: This is not a steel for beginners. There are no refunds for messing up these by forging them or heat treating them. This is a risky product for higher level makers who accept the risks involved in a product that consisting of high carbon steel, nickel and mild steel.. be warned.

Pro Tip: Don't grind these before heat treat. Flatten, profile but don't grind bevel. As the cheeks are not hardenable, there is no advantage to grinding profiles before heat treat. This only increases the chances of warping or issues during the heat treatment.

Heat treatment:

Aogami Super is not a beginner steel, do your own reseach online as there is some contrasting advice on heat treatment.

Jezz suggests to start your trials by what he does;

- hold time 7 mins at each temp

- 900 C

- 850 C

- 800 C

- 750 C

- up to 825 C, hold 7 mins and quench in fast oil

Temper 2 hours x 2 at 205 C.