Description

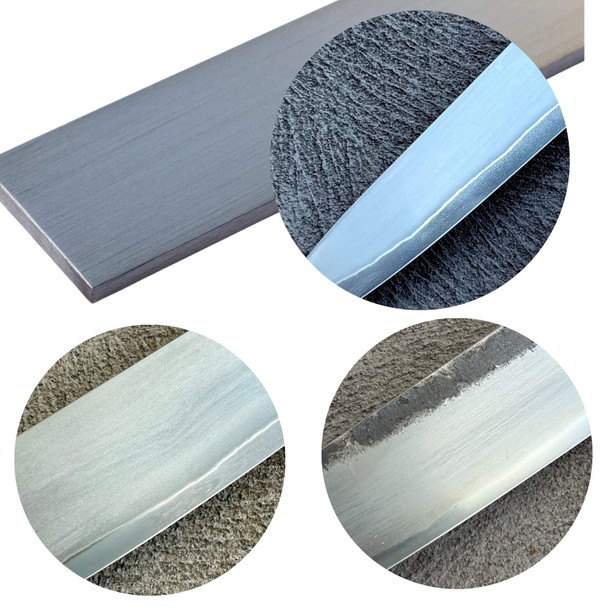

Stainless Steel San Mai Billet, Hardened and Tempered, HRC 58

"San mai" means the billet consists of a layered set of steels, not unlike a sandwich.

The core of the billet is 10Cr15CoMoV, a clone of the Japanese VG10 steel. This will etch black after grinding, with cladding in 316 Stainless Steel and pure nickel

Size: 3 x 50 x 330 mm.

So on each side of the core steel, there is another single layer of stainless steel for a total of 3 layers of steel- this is called "San Mai" plus one layer of pure nickel in between for a total of 5 layers if counting the nickel

Note these are PRE-HARDENED to approx 58 HRC and will be very difficult to work with hand tools.

These billets are stainless steel and make a great blade.

These are not to be heat treated, only to be used for stock removal. Take care to keep dunking in water while grinding to not ruining the temper.

After grinding and sanding, these can be etched in either ferric chloride or hydrochloric acid to make the 2 different steel types show up with different colours. Some bars are "very stainless" and you need the hydrochloric acid and longer time before you get a proper pattern, while others etch well in Ferric chloride alone.

Note these are laminated billets and require care when grinding - they are to be considered an "advanced" steel. If you do not grind evenly on both sides, the side with the thicker (stronger) cladding often pulls the blade that way.

Grinding laminated steel requires that you grind until you see core steel along the entire edge, then repeat on the other side. Do this while grinding back and forth on both sides to keep the cladding as even as possible until you see core all the way along the edge on the first side, then keep going on the other side. If the blade is now bent, straighten, or lightly keep grinding on the side the blade is bowing towards until the cladding is thinner and no longer pull the tip towards that side.