Description

How to Heat Treat 14C28N: Stainless Steel From Sandvik, Sweden

Many makers want to use stainless steel for a cleaner look in kitchen knives, in the past we have used to suggest 12C27 as the stainless steel to start with.

We suggest you might want to consider swapping to 14C28N, the next generation of 12C27 from the same maker:

- better edge retention

- can be hardened to higher HRC and retaining edge toughness (Sandvik recommends working hardness up to 62 HRC)

- smaller carbides than for instance 440C makes for easier, faster sharpening

- an improvement over 12c27 from the same maker, Sandvik steels

Heat treating 14c28N:

- Temperature 1060 C

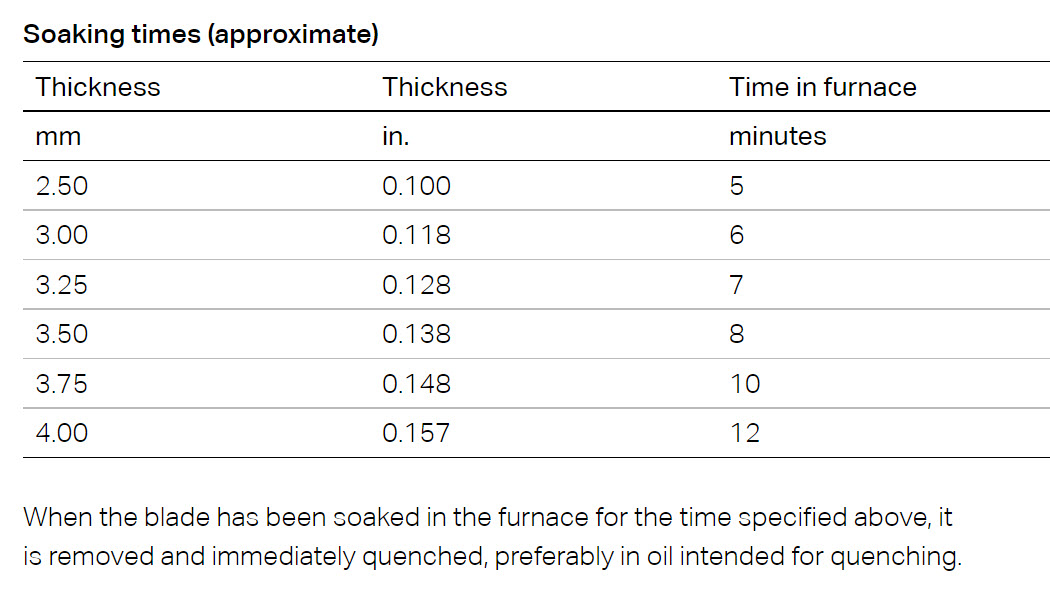

- Hold time 5 min (for 2.5 mm spine, see table below)

- Quench in oil or plates

- Basic cryo before tempering at -20 C (kitchen freezer) fo 30 mins

- Temper immediately at 175 C for 2 hours x 2 for about 60 HRC

*Sandvik describe tempering time required as only 30 mins per 2.5 mm thickness, but in the "More information" section say 2 hours so we would recommend 2 hours x 2 just to be sure. They also suggest 1050 C in the quick guide and then 1060 on the more detailed recipe, so we are using 1060 C here.

Rehardening is not recommended for stainless steels, get it right the first time.

Link to Sandvik heat treatment : https://www.materials.sandvik/en-au/materials-cen...

More details on 12C27 and 14C28N:

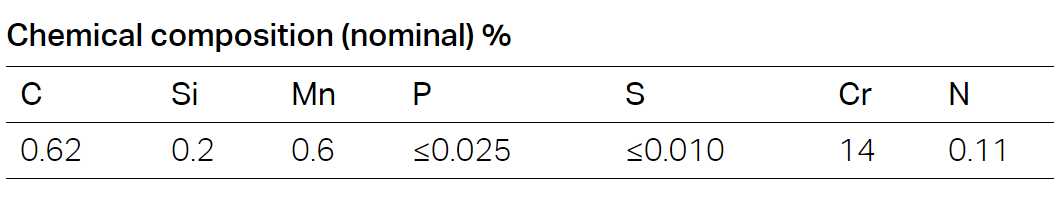

Stainless steels produced in Sweden by Sandvik. 12C27 is a good all-round blade steel – easy to sharpen and strop, holds a decent edge and is corrosion resistant. It is a good and popular steel for smaller knives. For bigger knives, 14C28N – an upgrade of 12C27 – is more suited as it can be hardened to a higher HRC value without losing its toughness. In most steels, carbon is used to increase hardness but 14C28N uses nitrogen. This allows for higher hardness without compromising corrosion resistance. All that makes the 14C28N a superior steel compared to 12C27 when it comes to tougher tasks such as batoning – better edge retention without compromising toughness or corrosion resistance.

Soak time before quench:

The below table from Sandvik is based on uniform material thickness. When we quench a blade with a 4 mm spine and 1.5 mm edge, how long to soak for? At Nordic Edge we have made a guesstimate that too long soak time at the right temperature for a few minutes extra will not negatively affect the edge, and soak based on spine thickness, not edge thickness. If this is the optimal solution, we are not certain of. Only listing here what we do with our own blades.