How To: Heat Treating Takefu V-taku2

- Gift wrapping:

- Options available

Description

How to heat treat Takefu V-Toku2 steel

After a bit of reading online and with the help of Jake Summerell from 116blades,

we have landed on the below for our own treatment of Takefu specialty steel v-Toku2.

This is a high carbon Japanese carbon steel often bought in san mai specialty steel with carbon steel damascus cladding, or stainless steel with brass and copper layers.

The below is not the official word from Takefu, only our take that is working well.

How to heat treat Takefu V-Toku2:

- hold at 750 C for 30 mins (1382 F)

- hold at 815 C for 10 mins (1500 F)

- quench in warm oil

- temper at 180 C for 2 hours x 2 (350 C)

My version with hammer texturing and heat treat and photos: LINK

Link to document from Takefu with the official heat treatment advice: LINK

Notes:

- Takefu document in last link says to temper from 120 C (248 F) for 65 HRC. We thought it might make sense to go for a somewhat stronger, less hard blade. Following Jake Summerrel's suggestion of 116Blades of 180 C for a somewhat softer, tougher edge.

- if your san mai steel includes brass - do not forge or bring higher in temperature than what listed here to not risk melting the brass.

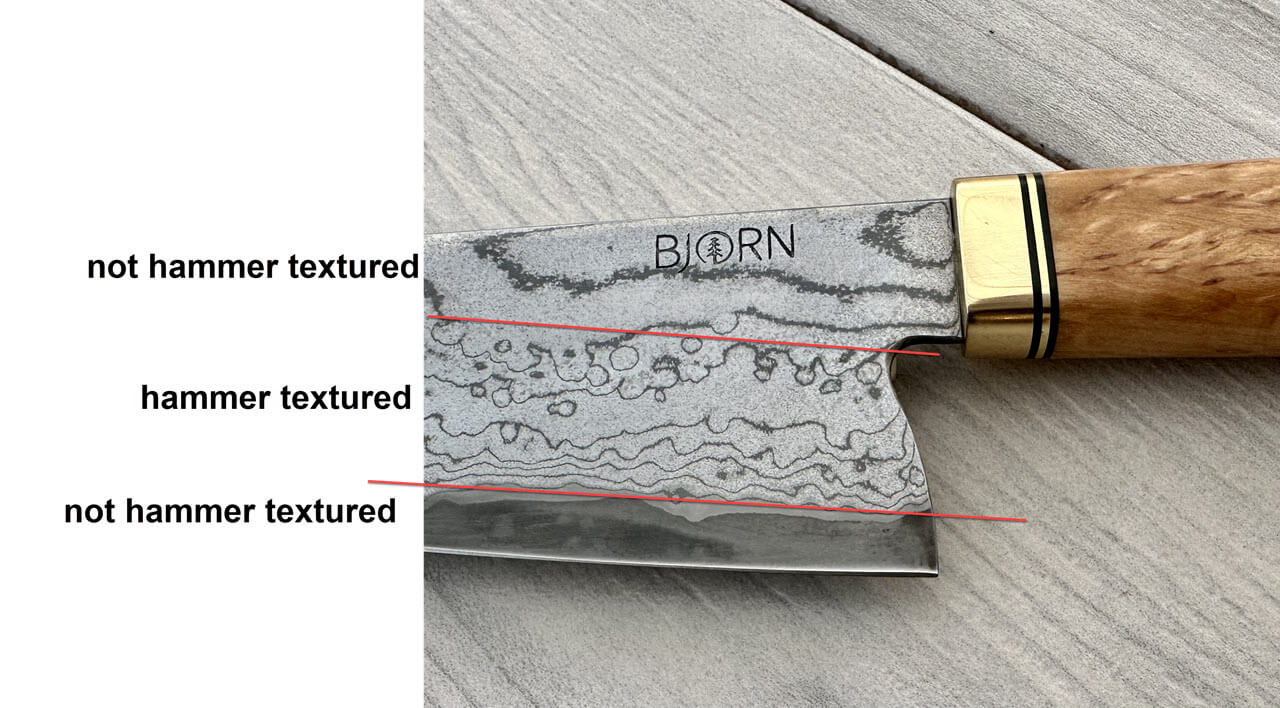

- If your san mai steel includes damascus side steel, consider hammer texturing like below for a more interesting pattern.

Hammer texturing:

- The takefu san mai billets with damascus cheeks have nice, uniform layers if ground as they come.

- For a more random pattern, hammer texture BEFORE hardening and tempering.

- Do not grind bevels before heat treatment, the sides are mild steel so there is no point. Just profile, then hammer texture and then harden and temper.

- Profile > hammer texture middel of blade sides > heat treat

- After heat treatment, draw a sharpy line 10 mm from the edge to not disturb the thin edge steel.

- Then draw a second sharpy line following the edge profile still, at the ricasso height.

- Hammer texture between the lines with the back of a ball peen hammer, this distorts the side steel layers.

- After grinding, the blade is etched in ferric chloride and the pattern appear in the textured section of the blade.