Description

How to make the handle scales for the Nordic Knife Design Beaver 70:

(These instructions will work for most any fulltang knife using 1/4" corby bolts and handle scales)

A tutorial how to make a NKD Beaver 70 knife using the blade, handle scales and 2 x 1/4" corby bolts:

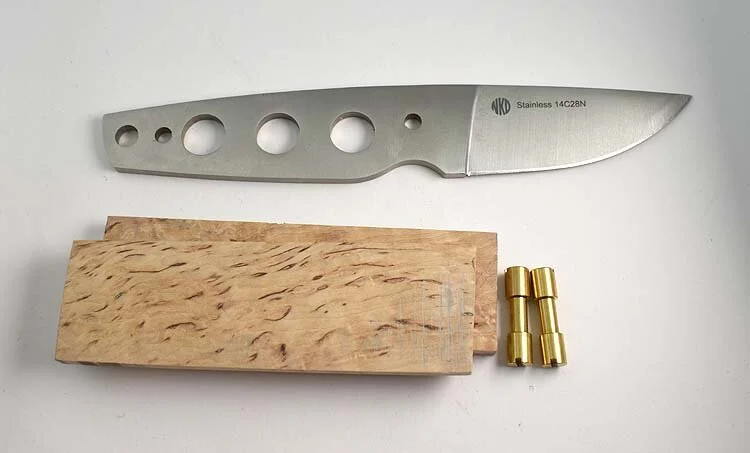

NKD beaver blade, flat ground curly birch, thickness 7 mm and 1/4" corby bolts:

Drill two holes 4.6 mm through the scale.

Drill through the other scale using the first as a jig for right distance between the holes.

Countersink 3 mm dept. If you do not have this tool, use a 6.3-6.4 mm drill bit.

Bandsaw or file off the excess wood around the handle profile. This step is optional but makes it a bit simpler later when the scales are being shaped.

Sand the front part before attching to the blade after rounding and evening the front out. This step also removes the issue of the scales not matching up 100%, as they are now filed to the same profile.

Sand the scales flush with the knife blade with a file or belt sander and then sand paper.

File down the bolts. With power tools you work faster, Do not overheat the bolts, not to burn the tree,

Now round the scales to your desired thickness and design. Do you want them thinner near the blade or thicker there? Flat the entire length of the handle or bowed out at the middle?

This is your handle, keep working the wood and try it out to see how you like the feel.

Finally sanded, colored and waxed handle. NKD Beaver 70 - a versatile EDC knife.