Description

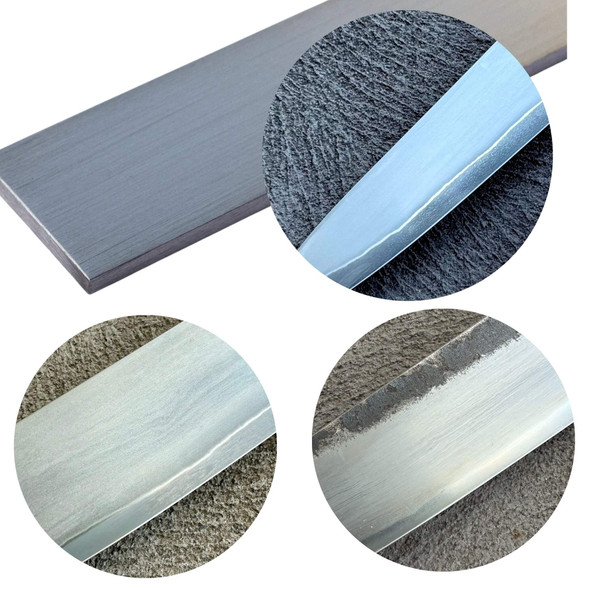

Cu Mai San Mai Billets from Oblivion Blades, Made in Australia

These are made to be forged or gently flattened hot and are as such not flat as monosteel bar stock.

**Note forging cu mai requires care to not delaminate the steel or melt the copper **

The billets are made by Jerarmie Heywood from Oblivion Blades. The billets consists of 1084 high carbon cutting steel with nickel and copper added as layers on each side of the cutting steel.

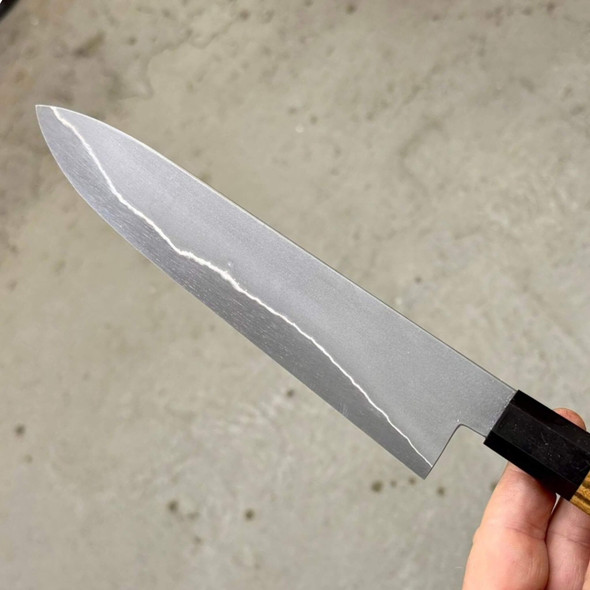

This creates a stunning looking blade when ground and etched.

As each is hand made they are different in size but weight is about the same, roughly 900 grams plus minus 50 grams.

The size is from 400-500 in length, from 50-65 in width and 3-4.5 mm in thickness to be forged to final shape or thickness.

Jerarmie has made a name for himself with custom billets of Japanese steels clad with nickel and mild steel, these are a version of that with 1084 to make them easier to heat treat.

- Mild steel 1020

- Nickel

- Copper

- Nickel

- 1084 high carbon steel as edge steel

- Nickel

- Copper

- Nickel

- Mild steel 1020

NOTICE: This is not a steel for beginners. There are no refunds for messing up these by forging them or heat treating them. This is a risky product for higher level makers who accept the risks involved in a product that consisting of high carbon steel, nickel and copper... be warned.

Pro Tip: Don't grind these before heat treat. Flatten, profile and grind off all corners to reduce the risk of the cladding ripping the core during the quench. Basically grind a 45 degree bevel/corner on all sides but don't grind the full bevel. As the cheeks are not hardenable, there is no advantage to grinding profiles before heat treat. This only increases the chances of warping or issues during the heat treatment.

If your steel splits during the heat treatment, try the grinding off corners above to reduce the strength of the cladding.