Blog

How To Heat Treat: CPM S35VN

Heat treating S35VN can be done at different levels of complexity. The below is the "ultimate" version from knifsteelnerd.com:

hold at 2025 F for 15 mins (1107 C)plate quenchliquid nitrogen/cryo treatment for 30+ minstemper between 300 - 400 F for 2 hours x 2 (149 C - 204 C)(adjust temp for hardness, aim for 60 HRC as a starting point)A simpler heat treatment recipe that is proven to work but provide a slightly lower HRC:

hold at 1950 F for 15 mins (1065 C)quench in oiltemper at 400 F (204 C)

…

25th Jan 2021

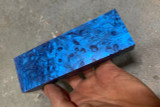

How To Cast Resin Handles

How To use: Knife Handle Casting ResinThese are the instructions for the knife handle casting resin mix from Maker's Choice.The kit comes with 2 bottles of resin, these need to be mixed together and then poured into a mold. Health warning: Epoxy should be kept off your skin and complete this process in a well-ventilated area, or better yet outdoors.If not using the entire kit, weight up the parts:Part A: 3 parts (for instance 150 grams)Part B: 1 part (for instance 50 gram)This will combine into

…

11th Jan 2021

How to heat treat Cu Mai billets

Cu Mai is an amazing-looking material in the right hands, but certainly not a beginner project.The laminated copper in between the steel and nickel makes it temperamental, and will require some experimentation but this is the recipe Jezz at Oblivion Blades succesfully use. He should know, he has made every bar we sell.The Cu Mai consists of 9 layers:1020 Mild steelNickelCopperNickel1084 High Carbon steelNickelCopperNickel1020 Mild steelThe nickel helps with the welding of the different mate

…

22nd Dec 2020

How To Grind A Blade Using A Bevel Jig?

If you have not watched the videos of Green Beetle on Youtube, you are in for a treat!He is funny, the videos are well put-together and in this one he even shows the Creative Man bevel jig.It is a good run-through of how he does it and he makes it entertaining to watch.From our experience with the bevel jig, there are 3 key points fo success:Expect a learning curve, not perfection on blade 1. Your hand pressure really matters, you need to focus in pushing evenly on both handles to get an even, f

…

21st Dec 2020

Heat Treatment for ELMAX steel

ELMAX Superclean is a powder "super steel" by Uddeholm known for excellent edge retention qualities and high toughness. The steel has 1.7% carbon and often tempered to 60+ HRC in use for knife blades:Uddeholm Elmax SuperClean is a high chromium-vanadium-molybdenum-alloyed steel

with the following characteristics: • High wear resistance

• High compressive strength

• Corrosion resistant • Very good dimensional stability

High wear resistance is normally connected to

low corrosion res

…

9th Dec 2020

How to get a good finish on forged items?

How to get a black, shiny finish on forged items.By Bjorn Jacobsen, 20th of Nov 2020.Many times when forging bottle openers, hooks and other little gadgets I have wished for a better looking finish than the scaled, mottled apparence straight from the forge.A little while ago a recipe was posted on a blackmithing group on Facebook about "pickling" forged items in citric acid and this is our results with this recipe plus some help from Mareko Maumasi.The challenge: Get a nicer finish by removing s

…

20th Nov 2020

Meet The Maker #12: Luke Andrew Cole

Creative Man: Meet The Maker Series - Luke Andrew ColeBy Riley Burns, 11/11/2020Luke Cole is a Brisbane based maker in his late thirties who has been a trade qualified jeweller for twenty years but his love for knifemaking began in his home town of Tamworth in northern nsw where he joined the local blacksmithing club while in high school. Luke’s interest in knives began with looking at historical knives and looking through his father's antiques collection and those of friends. He made his first

…

12th Nov 2020

Brisa Trapper in Elmax

Joe Kiss sent us a photo of his last project this week.The blade is from Finnish brand Brisa, the Trapper 95 mm in ELMAX stainless steel.ELMAX is a powder metallurgy stainless steel created by Bohler-Uddenholm. It is corrosive resistant due to its high Chromium percentage. It also has excellent edge holding capabilities. It is a fairly easy steel to sharpen and it becomes razor sharp due to the powder metallurgy process and the limited impurities.The handle scales are in Desert Ironwood with sta

…

6th Nov 2020

Knife and Blade Steel - what steel should I buy?

Beginner introduction to blade steelsSteel is an alloy, meaning it is a mixed element or a recipe of elements if you will. Unlike iron which is just that - iron - all the way through, steel is a mix of different elements. This is the reason there are so many different steels, each with somewhat different strengths and weaknesses. Mostly steel is iron with some added carbon, you might say steel is like re-inforced iron, making it stronger.To further improve the steel, other components

…

28th Oct 2020

New version of the Bevel Jig

Bevel Jig for fast, repeatable results The bevel jig is back in stock and this version has a couple of minor upgrades:harder bottom plate in Teflon, harder to scratch and less frictionoptional second tension arm to take up any slack in the hingesAt Creative Man we believe the bevel jig we offer is one of the best on the market; all stainless steel so will not rust or stick to metal dust, incorporates our Carbide Faced File Guide for matching plunge lines and with strong, accurate angle

…

28th Oct 2020